100 per cent detection and rejection reliability!

Another important milestone in the cooperation between Luye Pharma Group Ltd. and HEUFT Systems Technology (Shanghai) Co. Ltd: the fully equipped HEUFT spotter II PHS vial inspector which can currently be seen live at the CPhI Worldwide in Frankfurt and at the CIPM China passed the Site Acceptance Test (SAT) at the Luye location in Nanjing last week. It thus fulfils all the requirements to ensure full drug safety there.

After the successful preliminary Factory Acceptance Test (FAT) at the HEUFT production facilty in Burgbrohl, Germany, the straight-through inspection system has also proved its detection and rejection reliability where it will soon actually be in demand: directly in the new clean room packaging plant of one of the leading Chinese pharmaceutical manufacturers. Under real production conditions 1,000 20 ml vials each filled with lyophilized cancer preparations were sent into the compact HEUFT spotter II PHS in three test runs in order to check whether it is able to detect and remove each one of them which does not fulfil the specific safety and quality criteria of Luye Nanjing. And in fact: with a full 100 per cent accuracy – the 100 injection containers with typical faults were reliably detected in all three test runs and consistently rejected.

This applies in particular to a function specially adapted on site which detects the slight colour change of the sensitive lyophilisate occurring under the influence of oxygen. Shrunken lyo cakes, foreign matter above the product, cracks in the side wall and defective, leaking flanged caps were also reliably identified in all cases during the optical all-around inspection. And the unique pulsed HEUFT X-ray technology even made the smallest glass splinters visible in the freeze-dried medicine during the SAT in Nanjing.

Convincing detection accuracy

The acceptance also resulted in convincing values with regard to the false rejection rate: the proportion of good containers incorrectly rejected was less than four percent, a large proportion of them due to minor, non-critical deviations which were detected during the flanged cap inspection. However these can also be specifically taught in as good with the integrated HEUFT reflexx² image processing technology which should further reduce the false rejection rate in the future.

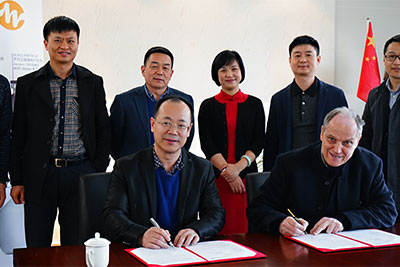

The SAT thus delivered really excellent results at Luye Nanjing which were subsequently celebrated with a drink.

The fully equipped vial inspector can be seen live at two pharmaceutical trade fairs until next Thursday, 7 November: CIPM China 2019, Stand S 3-30, in Chongqin and CPhI Worldwide, Stand 110B64 2019 in Frankfurt / Main.