Full container check

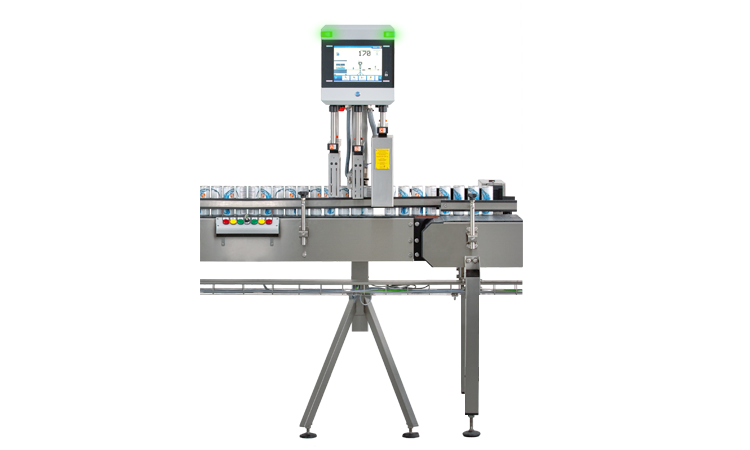

HEUFT PRIME

Finding quality defects quite easily: compact full container check with self-explanatory user guidance.

Inspecting the fill level, checking the presence, position and tightness of closures, detecting unlabelled full bottles, burst bottles and serial faults and consistently rejecting faulty products: this is easier than ever before with the HEUFT PRIME ! Because the compact full container check combines different detection technologies with a high degree of automation and the audiovisual HEUFT NaVi user guidance.

Fill level detection

Finding underfills and overfills reliably: the right technology for each application.

Too little, too much or exactly right: the HEUFT PRIME can be perfectly equipped with different detection modules for a precise fill level detection.

Read more...

It checks the filling quantity of transparent bottles with infrared technology highly precisely. The high frequency measurement provides exact results for all types of non-metal containers – and compensates foam which may be present in the course of this. This reduces the false rejection rate on filling lines for beer or carbonated soft drinks. X-ray technology for determining the filling quantity exactly is used if the containers are opaque.

Fullscreen

Closure detection

Checking the tightness: special procedures for different closures.

Missing, incorrectly positioned and leaking: the HEUFT PRIME identifies closure faults such as these reliably. Different procedures are used for this: it checks the presence and position with special sensor and optical technologies. Therefore missing closures or closure elements which are too high are noticed immediately. The same applies to deviating closure curvatures which draw conclusions about the internal pressure and consequently the tightness of the containers.

Fullscreen

Label check

Paying attention to the labels: specific examination of the presence.

Collar, body, neck or wrap-around label: there must not be any missing! The HEUFT PRIME checks whether this is really the case by means of special sensors which make use of the different reflection characteristics of the container surface and the label. Therefore it is immediately clear when one or several of them are missing. The sensors can be directly integrated in the labeller. A presence check is also possible whilst the containers are being transported on the conveyor as an alternative.

Fullscreen

Serial fault detection

Noticing the repeated occurrence of defects in good time: locator for safeguarding productivity.

Specific, in good time and sustainable: the HEUFT PRIME prevents faults from becoming serial faults and impairing the productivity of the complete filling and packaging line. For example an integrated locator function records when a particular filler valve regularly underfills in good time.

Read more...

A switch-off pulse is emitted when the number of faulty fillings exceeds a certain, individually adjustable threshold value. Therefore malfunctions can be rectified before they can threaten the safety and quality of complete batches and cause rejection rates which are too high. The HEUFT PRIME also notices recurring closure and labelling faults in good time and prevents these from going into production and thwarting the efficiency and productivity of the whole line by means of a stop signal.

Fullscreen

Fault rejection

Preventing recalls: the reliable rejection of faulty containers.

Fast, careful and accurate: highest precision when detecting faults is only effective if the products in question are also removed afterwards. The single-segment and multi-segment rejection systems of the HEUFT rejector series deal with this both precisely and carefully.

Fullscreen

Product monitoring and self-tests

Playing it safe: exact product tracking and regular self-tests.

Always knowing the current location of a particular product: each one is tracked precisely for this. This ensures that none remain uninspected.

Read more...

The integrated reject verification checks that each product identified as faulty is really removed. Standard test programs guarantee a regular examination of the detection performance. Network-based continuous documenting and long-term archiving of the results.

Fullscreen

Optional additional functions

Detecting even more: extensions to the range of functions.

The range of functions of the HEUFT PRIME with its modular design can be extended at any time. Thus the HEUFT sonic module checks the tightness of metal closures highly precisely. The optionally available bottle burst detection registers bottles which burst in the filler immediately and draws the right conclusions: not only are these rejected but also adjacently filled bottles and those which have been filled during the subsequent circuits with the same valve. Therefore products contaminated with glass splinters cannot reach the customer.

Fullscreen

HEUFT NaVi

Simply knowing what to do: self-explanatory audiovisual user guidance.

Intuitive, individual and audiovisual: previous knowledge is not required in order to operate the HEUFT PRIME reliably. The HEUFT NaVi user guidance is self-explanatory and supports the respective user step by step.

Read more...

An RFID login with user-related access rights provides an overview and makes the respective user's work simply easy: he only sees what he really needs to on the clearly arranged touchscreen user interface with a flat menu structure, integrated tutorials and precise auxiliary tools in order to fulfil his specific tasks optimally. He is supported by a virtual assistant in the course of this. She speaks to him and clearly explains what has to be done when and where. Purposeful and focussed on the essentials – the audiovisual HEUFT NaVi user guidance makes the reliable operation of HEUFT systems simply easy!

Fullscreen

HEUFT checkPoints

Simply seeing where what has to be done: trouble-free localisation.

Clear, direct and purposeful: the user can cope immediately on the rare occasions when manual intervention is needed. Because eye-catching HEUFT checkPoints make it clear at a glance exactly when it is necessary to take matters in hand in addition to the audiovisual information which the HEUFT NaVi provides.

Read more...

The orange tags not only flash on the touchscreen but also at the respective component if the worst comes to the worst. The problem is located without a long search. This saves time and human resources, shortens standstills and therefore increases productivity.

Network technologies

Networking everything: online connection for increased efficiency and quality.

Information transmission in real time, production data acquisition, line analysis and remote maintenance: networking is the answer!

Read more...

HEUFT systems have future-proof network interfaces (Gigabit Ethernet and TCP / IP) for an online connection via the Internet and the database interface (SQL / DDE) for top line efficiency and an optimum quality management with considerably faster and easier workflows. Therefore production data, shift records, productivity faults and HACCP limit value analyses are available network-wide. The result: early identification of quality and efficiency problems. The firewall protected direct connection to the HEUFT TeleService makes competent remote maintenance possible all around the clock.

HEUFT rejector

Removing faulty products: the right rejector for all cases.

For example, the single-segment HEUFT flip and HEUFT mono rejectors as well as the multi-segment HEUFT DELTA-FW and HEUFT DELTA-K systems are ideally suited for the reliable rejection of faulty full containers.

- all the basic functions for a full container check in one compact device

- automatic vertical adjustment for all the detection units for easy and fast brand and format changes

- self-explanatory HEUFT NaVi user guidance with integrated auxiliary tools and extensive audiovisual step-by-step assistance

- clear touchscreen user interface concentrating on the essentials and rapid login with personalised access levels

- attractive price due to series production

- performance range – up to 72,000 containers per hour

- reduction of the false rejection rate during the closure detection up to 0.01 %