Leakage check

HEUFT squeezer QS

Finding leaks and closure faults: leakage check for plastic containers.

Particularly sensitive pharmaceutical products such as medicinal syrups, food supplements or enteral food are frequently filled into containers and pouches made of plastic such as HDPE and PET. The safety of the product and with that the health of the consumer is seriously put at risk if they should leak.

Leakage check

Finding leaks reliably: a comparative fill level detection and measurement of the internal pressure.

Leaks, stress cracks and microcracks: the HEUFT squeezer QS measures the internal pressure on the one hand and in addition carries out a comparative fill level detection in a compressed and non-compressed condition in order to find filled containers and pouches made of plastic with such faults reliably.

Read more...

A precisely controlled amount of pressure is exerted on the containers for this. The internal pressure falls while the fill level rises if there is a leak. A correlated evaluation of the fill level and internal pressure measurements refine the result. Even the smallest leaks are reliably tracked down in this way. This safeguards the integrity of the product as well as the stability and steadiness of the container. The conveyor belt guiding the containers adapts itself automatically to the changed format for fast, fully automatic brand changes.

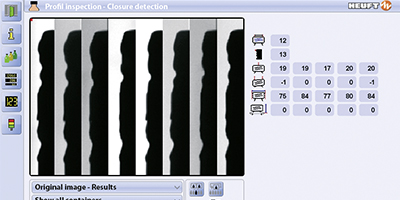

Closure detection

Ensuring tightness: different possibilities for checking the closures.

Missing, canted and defective: closure faults such as these threaten the tightness of the packaging just as the quality of its contents. Different technologies for a closure detection can be integrated into the system in order to uncover them reliably.

Read more...

It can check the presence, position, completeness, integrity and brand affiliation of the closures precisely with special sensor, camera or ultrasonic technology depending on the requirements. Thus the HEUFT squeezer QS provides the best results for every application and safeguards the tightness of the container sustainably as well as the quality of the product contained in it.

Fault rejection

Preventing recalls: the reliable rejection of faulty containers.

Fast, careful and accurate: highest precision when detecting faults is only effective if the products in question are also removed afterwards. The single-segment and multi-segment rejection systems of the HEUFT rejector series deal with this both precisely and carefully.

Product monitoring and self-tests

Playing it safe: exact product tracking and regular self-tests.

Always knowing the current location of a particular product: each one is tracked precisely for this. This ensures that none remain uninspected.

Read more...

The integrated reject verification checks that each product identified as faulty is really removed. Standard test programs guarantee a regular examination of the detection performance. Network-based continuous documenting and long-term archiving of the results.

Optional additional functions

Detecting even more: extensions to the range of functions.

The HEUFT SPECTRUM systems with their modular design can be extended at any time. Camera, high frequency or X-ray technology is available for the fill level detection depending on the product and the task. The HEUFT VISION 360 module carries out a high-precision optical closure inspection as an option.

HEUFT SPECTRUM TX

Controlling centrally: one platform for all requirements.

Precise, network-compatible and cross-system: the HEUFT SPECTRUM TX forms the basis for different technologies, modules and functions. The devices of the generation of the same name can be exactly adapted to individual requirements on site and retrofitted at any time due to this universal platform.

Read more...

A cross-system component equality of 70 per cent ensures a high availability of spare parts. The central HEUFT SPECTRUM TX control unit creates a high level of precision during continuous product tracking and quality assurance due to its multiprocessing capability. A future-proof network connection ensures reliable remote maintenance and production data acquisition for optimum efficiency and productivity. In-house developed hardware and software and its own operating system ensure computing power and offer no opportunity for viruses or malware.

HEUFT reflexx

Combining photographs and reliably detecting objects: image processing in real time.

Fast, powerful and exact: combining several camera and X-ray images with each other and specifically detecting various objects. The HEUFT reflexx carries out all this in real time.

Read more...

The in-house developed hardware and software provides high computing capacity and is exactly tailored to the requirements of the in-line quality inspection. It generates high-resolution, noiseless detection pictures and analyses them precisely. Integrated filter technologies clearly differentiate between supposed and actual faults. This reduces the false rejection rate sustainably.

HEUFT PILOT

Operating HEUFT systems reliably: graphical user interface with practical tools.

Clear, helpful and specific: the HEUFT PILOT graphical user interface convinces due to an easy to understand, multilingual menu structure with extensive auxiliary tools. Therefore the reliable operation of the HEUFT SPECTRUM TX systems is not difficult.

Read more...

Important information and clear error messages with service notes provide the respective user with specific support. This avoids incorrect adjustments and shortens standstills e.g. during brand changes. Password protected operator levels adapted to the respective area of responsibility also contribute to this. Also integrated: a complete online user manual and a tool for the uncomplicated identification and direct ordering of spare parts.

Fullscreen

Network technologies

Networking everything: online connection for increased efficiency and quality.

Information transmission in real time, production data acquisition, line analysis and remote maintenance: networking is the answer!

Read more...

HEUFT systems have future-proof network interfaces (Gigabit Ethernet and TCP / IP) for an online connection via the Internet and the database interface (SQL / DDE) for top line efficiency and an optimum quality management with considerably faster and easier workflows. Therefore production data, shift records, productivity faults and HACCP limit value analyses are available network-wide. The result: early identification of quality and efficiency problems. The firewall protected direct connection to the HEUFT TeleService makes competent remote maintenance possible all around the clock.

HEUFT CleanDesign

Cleaning quite simply: hygiene-optimised construction.

Accessible, clean and safe: its HEUFT CleanDesign predestines the system for use in hygienically sensitive areas.

Read more...

Sloping surfaces facilitate cleaning and prevent the accumulation of stubborn dirt. Special channels and openings allow the liquids required for cleaning purposes to be drained off completely. Consequently dangerous germs and bacteria have no contact surface whatsoever. Specially constructed casings and doors create optimum accessibility. The electronics are totally encapsulated. Sensitive areas such as the inspection units are dust-proof and protected against contact as well as water jets.

HEUFT rejector

Removing faulty products: the right rejector for all cases.

For example, the single-segment HEUFT flip and HEUFT mono rejectors as well as the multi-segment HEUFT DELTA-K and HEUFT DELTA-FW systems are ideally suited for the HEUFT squeezer QS.

- continuous quality assurance by means of online detection

- sustainable safeguarding of the stability and steadiness of plastic containers with thin walls

- high detection performance due to the unique linking of different measuring procedures

- servo-controlled adaptation of the conveyor belt for uncomplicated brand and format changes

- hygiene-optimised HEUFT CleanDesign

- online connection for remote maintenance and production data acquisition

- performance range – up to 1,200 containers per minute

- false rejection rate < 0.1%