SOLICITUD

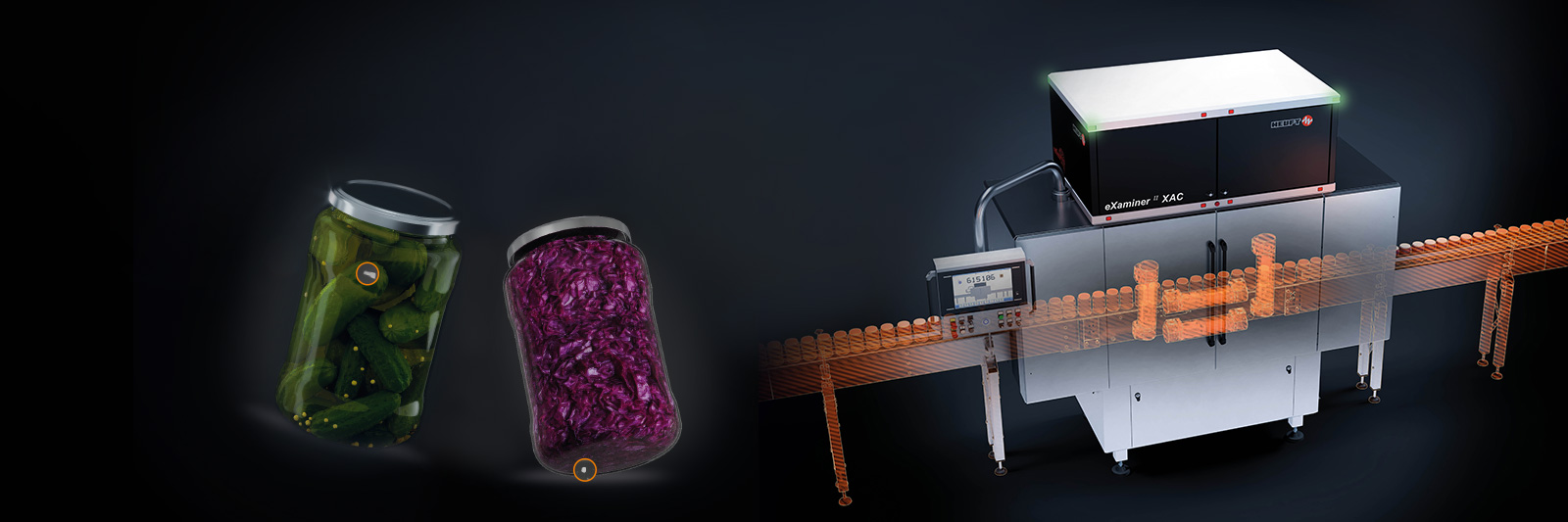

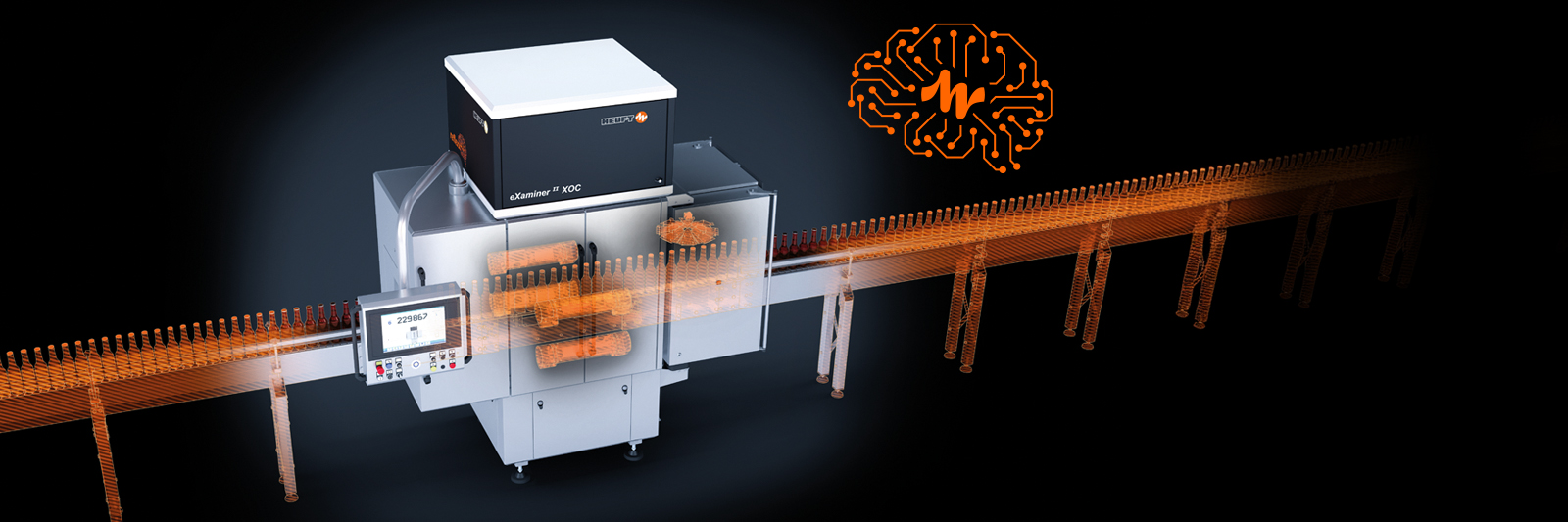

HEUFT es SYSTEMTECHNIK

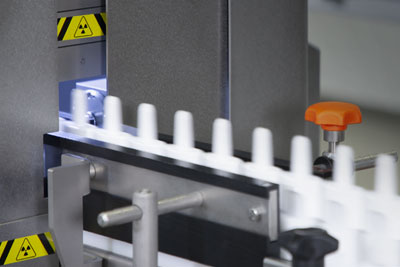

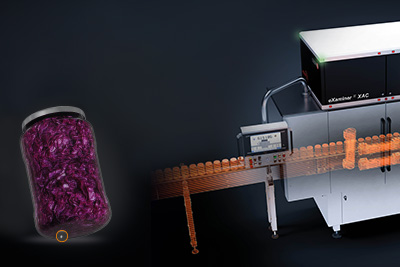

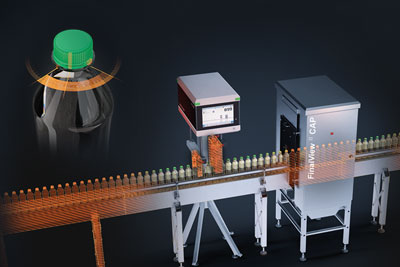

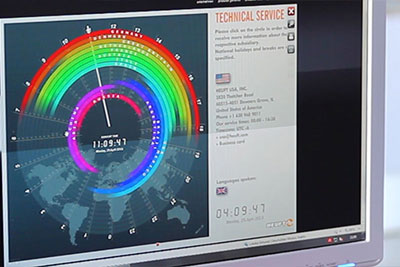

Calidad, seguridad y eficiencia: es lo que importa cuando hablamos de envases y cajas de bebidas, alimentos y productos farmacéuticos! La solución modular de HEUFT SYSTEMTECHNIK GMBH hace que estos factores resulten claves mediante una práctica simple y efectiva. Se aseguran, durante una productividad máxima, que sólo lleguen al mercado aquellos productos que se encuentren en perfectas condiciones.