Reuse? For sure!

Fill beverage bottles and food jars more than once? With the right equipment and know-how for sorting and inspecting empties, this can be done safely and without any defects.

Reuse, refill, recycle: at the latest since the "Loi AGEC", the law to combat waste and promote the circular economy, came into force last year, this has become increasingly relevant in France. According to this law, single-use plastic packaging may no longer be put into circulation at all from 2040 onwards. And regarding beverage bottles and food jars made of glass, the law also aims to prevent waste, stop littering and make reuse the rule.

In order to be able to refill them safely and in a resource-saving manner the sensitive primary packagings must therefore be unmixed, free of faults and uncontaminated. We at HEUFT have exactly the right equipment for empty bottle sorting, all-surface empty bottle inspection and gentle upright rejection in tightest space – and decades of experience in the returnable and non-returnable sectors. Our modular systems "made in Germany" are not only the first choice for checking the quality of the bottle pool directly in the filling line. They perform just as well in external collection and washing centres for reusable glass containers, which are becoming increasingly important in France.

Careful sorting

From wine, water, fruit juice or milk bottles to jam or yoghurt jars: QA systems from our modular construction kit check with high precision whether the packaging materials can really be refilled safely or should better be discarded in time.

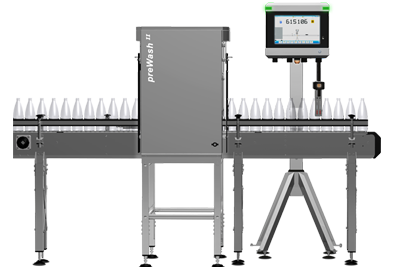

After a rough infeed check has rejected overheight, lying or defective containers the HEUFT SPECTRUM II SX empty bottle sorting system with the innovative HEUFT preWash II module frees the production flow from foreign bottles and jars which cannot be cleaned safely:

- Bottle colours are reliably identified and clearly differentiated from each other. The same applies to residual liquids such as blue lye which can impair the cleaning performance of the washing machine.

- Soiling, scuffing, but also embossings and ACL labels in the glass are detected by the colour camera inspection and used as a clue for sorting out non-brand containers.

- Non-removable labels and glue residues of self-adhesive labels that cannot be removed in the washing machine, making it difficult to relabel and reuse the container in question, are also identified.

Gapless empty container inspection

All-surface empty bottle inspectors (ASEBIs) of the current HEUFT InLine II range check the cleaning performance immediately after an optionally available infeed check for the rough sorting out of containers of deviating formats:

- Containers which are still contaminated after washing are reliably detected; the HEUFT fluid module detects even the smallest amounts of residual liquids such as corrosive washing lye.

- Chips and cracks in the glass as well as mould or even transparent film in the container are identified during the completely covering optical sidewall, finish and base inspection with smart HEUFT reflexx A.I. image processing.

- The smallest glass splinters in the residual liquid are made visible by the pulsed X-ray inspection exclusively available from HEUFT.

From the particularly compact entry-level model to the X-ray supported premium ASEBI – HEUFT defines the state of the art during the empty container inspection and has exactly the right solution for every application:

The HEUFT InLine II IR combines a proven design with full flexibility during space-saving integration and detection and operating reliability at HEUFT SPECTRUM II level on a footprint of only one square metre.

The highly automated HEUFT InLine II IS is designed to be particularly hygiene and maintenance-optimised and represents the current standard for the complete inspection of empty containers without gaps.

The fully equipped HEUFT InLine II IX is the only ASEBI to date to feature pulsed X-ray for the precise glass-in-glass detection in addition to proven detection units.

Equipment and advice

Based on the universal HEUFT SPECTRUM II device platform with audiovisual HEUFT NaVi user guidance our network-capable sorting and inspection devices achieve maximum computing power, automation, operating and detection reliability during the examination of up to 74,000 containers per hour. Sort and format changes are quick and easy: all parameters are automatically adjusted, the height and position of the detection units are adjusted without manual intervention. The HEUFT LAMBDA-K, for example, is ideal for the gentle upright rejection and sorted distribution of unsuitable empty containers. As our example layout shows it can be integrated into collection and washing stations for refillable glass containers just as flexibly and space-savingly as our compact QA systems.

HEUFT not only supplies the right equipment for superior detection and rejection reliability. Our engineering team also develops the suitable concept for the efficient insertion and installation in external washing centres for your individual application on site – and implements it optimally with HEUFT conveyor belts and HEUFT synchron conveyor controls for efficient container transport. We will be pleased to demonstrate to you what is involved, for example during a practice-oriented workshop in the showroom of the HEUFT SYSTEMTECHNIK GMBH customer centre in Germany.

Our experts from HEUFT FRANCE can of course also offer you intensive advice on all questions concerning the sorting and inspection of refillable glass containers. Are you interested? Then send us an e-mail right away to reuse@heuft.com.