Full case inspection

HEUFT GX

Checking outer packaging specifically: precise full case inspection.

The HEUFT GX checks the quality features of the newly packed outer packaging of pharmaceutical containers such as trays and cardboard boxes. It identifies deformations, raised cardboard box flaps, incorrect colours and logos just as reliably as missing units inside the case.

Shape check

Ensuring transportability and unpackability: detecting distorted cases.

Stackable, transportable and functional: full cases should be in top shape. Otherwise they cannot be stacked, transported or stored. Furthermore distorted cases and cardboard boxes make it difficult to remove the containers contained in them. Therefore the HEUFT GX only allows outer packaging to pass which is in top shape. It checks its dimensions and measurements for this using sensors. The full cases in question are removed before being loaded if these deviate from the specifically determined limit values.

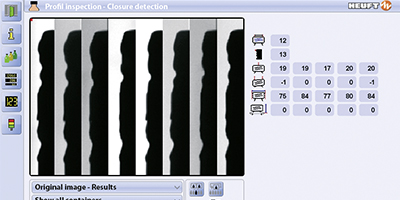

Cardboard box flap check

Detecting raised flaps: checking they are closed.

Falsely positioned, raised and incorrectly closed: this not only looks unsightly if this is the case with regard to the flaps of cardboard boxes for drinks. In addition the effectiveness of the outer packaging and the safety of the sensitive contents contained in it are at risk. Therefore the HEUFT GX checks the position of the flaps and that they fit correctly ensuring that the complete case is closed. Sensors scan its edge areas for this. The measured values change if they are covered by raised flaps. Thus the respective outer packaging is detected reliably.

The rejection of faults

Preventing recalls: the reliable rejection of faulty cases.

Fast, careful and accurate: highest precision when detecting faults is only effective if the products in question are also removed afterwards. The device either emits a conveyor stop signal or activates the corresponding rejection system, such as the HEUFT xcase, in order to remove incomplete cases from the production flow.

Monitoraggio del prodotto e auto-test

Andare sul sicuro: tracciare esattamente il prodotto ed eseguire test di funzionamento a scadenza regolare.

Conoscere sempre la posizione esatta di ogni prodotto grazie a un sistema molto preciso di tracciamento. Questo assicura che nessun contenitore venga trascurato dall’ispezione.

Leggi di più...

La verifica integrata di avvenuto scarto controlla che ogni prodotto classificato come difettoso venga effettivamente deviato dal flusso produttivo. Programmi automatici di test assicurano un controllo periodico delle prestazioni di rilevamento. E’ possibile inoltre il monitoraggio continuo tramite rete Ethernet e l’archiviazione a lungo termine dei risultati.

Simple brand changes

Changing automatically: automatic adjustment of the detection units.

Reliable, uncomplicated and easy: the HEUFT GX carries out brand changes without manual intervention. All the parameters are adapted automatically and the height and position of the detection units adjusted by motor. This practically rules out misadjustments saving valuable time and money.

Optional additional functions

Making even more possible: extensions to the range of functions.

The HEUFT GX with its modular design can be extended at any time. Thus the following additional functions, among other things, can be integrated:

- A special camera system reliably differentiates between different case colours for highest brand purity. Three measuring windows can be determined for this so that differently coloured promotional stickers and symbols do not distort the result.

- The reliable detection of non-brand logos is also achieved optically. Up to seven different logos can be photographed and compared to the stored original in this way.

- The precise detection and differentiation of barcode labels is carried out by a special sensor system.

HEUFT SPECTRUM TX

Controlling centrally: one platform for all requirements.

Precise, network-compatible and cross-system: the HEUFT SPECTRUM TX forms the basis for different technologies, modules and functions. The devices of the generation of the same name can be exactly adapted to individual requirements on site and retrofitted at any time due to this universal platform.

Read more...

A cross-system component equality of 70 per cent ensures a high availability of spare parts. The central HEUFT SPECTRUM TX control unit creates a high level of precision during continuous product tracking and quality assurance due to its multiprocessing capability. A future-proof network connection ensures reliable remote maintenance and production data acquisition for optimum efficiency and productivity. In-house developed hardware and software and its own operating system ensure computing power and offer no opportunity for viruses or malware.

HEUFT reflexx

Combinazione di fotografie e rilevamento affidabile di oggetti: elaborazione immagini in tempo reale.

Velocità, potenza e precisione: combinare assieme immagini da telecamere e moduli a raggi-X e riuscire a rilevare specifici oggetti. La tecnologia HEUFT reflexx svolge in tempo reale tutti questi compiti.

Leggi di più...

Hardware e software sviluppati da HEUFT forniscono un’elevata capacità di calcolo e sono configurati esattamente per venire incontro alle esigenze del controllo qualità della linea produttiva, producendo immagini di rilevamento ad alta risoluzione e analizzandole con precisione. Le tecnologie di filtro integrate, poi, distinguono chiaramente tra difetti reali o solo presunti. In questo modo si riducono decisamente i falsi scarti.

HEUFT PILOT

Lavorare con I sistemi HEUFT in modo affidabile: interfaccia utente grafica e pratica.

Chiara, utile e precisa: l’interfaccia grafica HEUFT PILOT è corredata di menù multilingue facili da capire e di diversi strumenti ausiliari. Pertanto l’utilizzo dei sistemi HEUFT SPECTRUM TX non è difficoltoso.

Leggi di più...

Importanti informazioni e chiari messaggi di errore forniscono all’utente un supporto specifico. Questo evita regolazioni sbagliate e riduce i tempi di fermo,ad esempio per i cambi formato. Livelli operatore protetti da password sono configurati in base all’area di competenza dell’operatore, cosa che contribuisce alla facilità d’usa del dispositivo. Sono inclusi: un completo manuale online e uno strumento per identificare e ordinare le parti di ricambio in modo semplice.

Fullscreen

Tecnologie di rete

Tutto in rete: essere “online” per far crescere efficienza e qualità.

Trasmissione di informazioni in tempo reale, acquisizione dei dati di produzione, analisi della linea e manutenzione da remoto: la rete è la risposta!

Leggi di più...

I sistemi HEUFT sono dotati di interfacce all’avanguardia di rete (Gigabit Ethernet e TCP / IP) e di database (SQL / DDE) per la massima efficienza della linea e del controllo qualità, con flussi di lavoro più veloci e semplificati. Pertanto dati di produzione, registri degli accessi, difetti di produttività e analisi dei valori HACCP sono disponibili online. Il risultato di tutto questo è una precoce identificazione dei problemi. La connessione ai servizi di HEUFT TeleService è protetta da firewall e garantisce l’assistenza remota 24 ore su 24.

Removing faulty cases

The right rejector for all cases.

Discharging, rejecting and distributing: HEUFT rejection systems for packaging remove faulty crates, cardboard boxes, trays or shrink wrap packages reliably from the production flow. They achieve maximum performance optimally matched to their respective task with regard to precision and carefulness.

- The HEUFT xcase guarantees brand purity in the bottling hall. Its load-dependent control system which adapts the force of the rejection impact to the weight of each individual case removes non-brand and faulty bottle crates smoothly from the filling line. Crates of varying weights are therefore each rejected an equal distance.

- The HEUFT xtray removes damaged or faulty trays with full containers from the line. For this three rejection fingers which are on a sledge installed under the roller conveyor are extended. Trays can also be distributed onto several lanes if several of these intelligent case rejectors are lined up next to each other.

- The HEUFT maxi-flip rejects empty, half-full or completely full cases each an equal distance onto parallel conveyor chains. Its rejection segment is activated for a longer time in the case of heavy crates or cardboard boxes than for lighter ones. A complex mechanical changeover for different types of cases is not necessary.

- The HEUFT maxi-laner is a space-saving alternative to the HEUFT maxi-flip. The compact system which is installed directly above the conveyor is also impressive with a load-dependent control system. It always rejects crates of different masses and varying weights equally. Distributing the cases onto three lanes is also possible with the HEUFT maxi-laner.

- continuous quality assurance of filled outer packaging

- precise examination of up to 120 full cases per minute

- uncomplicated integration into existing lines

- fully automatic brand changeovers

- simple upgrading and retrofitting due to modular design

- compact, easy to clean construction

- online connection for production data acquisition and remote maintenance with the HEUFT TeleService