空罐检测

HEUFT canLine II

最佳状态的空罐:灌装易拉罐时的安全和高效。

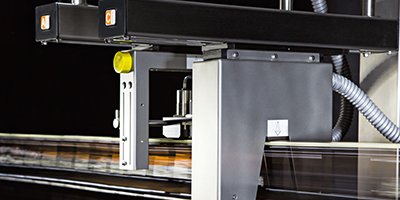

在故障饮料罐降低灌装线的生产效率并危及最终产品的安全之前对其进行检测和移除:极为简洁的HEUFT canLine II比以往任何时候都更有效地进行空罐检测以防止封盖机堵塞和产品污染。 这不仅能通过高度自动化的HEUFT SPECTRUM II平台实现,之外,带有自动调节LED照明的智能传感照相机也能够做到。

瓶口和卷边检测

检测变形和保证密封性:罐装易拉罐时的整线效率和包装完整性。

畸形、扭曲和凹陷:空罐的颈部区域形状有偏差或卷边边缘有凹痕,会危及灌装过程的效率和生产率以及整个容器的密封性和完整性。例如,如果空罐的上部开口是椭圆形而不是圆形,则罐盖将无法安装在罐上。结果造成:封盖机的堵塞会导致停机,影响整个易拉罐生产线的效率下降。即使能够进行密封,诸如间断的、凹陷的凸缘边缘等缺陷也会危及成品初级包装材料的密封性,从而影响饮料内部的微生物纯度。

更多...

因此,只通过带有一个内部研发的传感器彩色照相机在灌装前对饮料易拉罐进行无接触的至上而下的检测,不仅可以在最小的空间内进行高度精确的椭圆度检测,而且还可以识别容器开口周围的其他变形和缺陷。因此,在空罐可能引起更严重的封盖机问题或导致满罐泄漏之前,将其移除。

内侧壁和瓶底检测

识别凹痕、污染和异物:用于全面产品安全性的空罐检测。

景深造就高性能:创新的彩色传感器照相机在对空罐进行自上而下的检测时能够自动调节高度,不仅有一个集成的图像转换器和带有单独控制的LED自适应照明以获取最佳的可视性,还具有这样的景深,甚至是凹痕或者高污染的内侧壁及瓶底的污渍和异物也能也能清晰可见——结合带有学习能力的HEUFT reflexx A.I 实时图像处理系统。

更多...

因此,优化的光学检查覆盖了每个空罐的所有安全相关区域,从上到下,一次只有一个图像。连接到功能强大、高度自动化的带有HEUFT NaVi视听用户指南的HEUFT SPECTRUM II控制单元,它还能沿着高速产线在最狭窄的空间内进行全面的空罐检查,以确保消费者手中的最终产品的安全。

Fullscreen

剔除不合格包装

减少召回:剔除不合格容器的可靠性

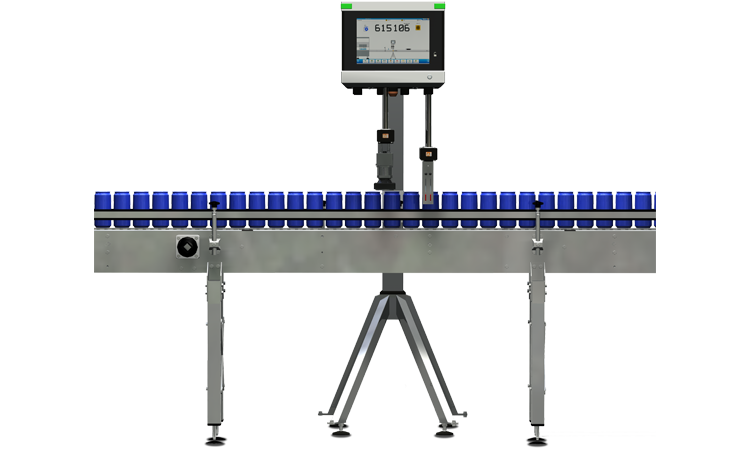

快速、平稳、精准:只有当不合格产品从生产线上被剔除时,检测的高精度才有意义。HEUFT rejector系列的单段或多段剔除系统能精准且平稳地实现这一点。

Fullscreen

确切的产品追踪和定期的自我测试

产品监控和自我测试使其安全:确切的产品追踪和定期的自我测试。

始终清除某一特定产品的当前位置:每一个都被精确追踪,并确保没有未经检测的。集成的剔除确认能够检查每一个被认定为错误的产品准确地被移除。标准的测试程序能确保检测性能的定期检查。基于网络连续记录和长期归档结论

瓶型更换简便

自动适应:自主和辅助格式更改。

罐装线上每天执行罐型和型式的更换。HEUFT canLine II所基于的更高级别的HEUFT SPECTRUM II平台已经具备了前所未有的自动化水平和对用户的支持,以便快速、轻松、无误地执行任务:智能彩色传感器摄像头的高度与检测区域中导轨的通道宽度一样能自动适应新的瓶型格式。HEUFT NaVi在这一过程中为用户提供了逐步的视听帮助,这使得瓶型更换变得简单易行。创新的自适应LED照明直接集成在传感器照相机中,无论是标准饮料罐、还是各种颜色的纤体罐,它也能完全自动调整以适应瓶型更换:可单独控制的LED照明为检测区域内的每种空罐提供精准的照明,无阴影无反射。所有罐型的调整都永久存储在系统里,在任何时候都可以再生产。

可选附加功能

检测更多:功能范围的扩展。

模块设计的HEUFT SPECTRUM II系统易于扩展。因此,HEUFT canLine II的功能范围可以选择性的扩展简洁和安全的封闭式检测单元,如增加检测单元用于外侧壁的光学360°检测。这样,有划痕的、印刷错误的、不正确标识的外来的罐子甚至可以在被灌装前就被追踪到并分类出来。带自动寻找参数功能的高性能图像处理系统,有记忆个体质量要求的能力。保证只有那些外观完好及贴牌无误的罐子才可以进入市场。

HEUFT SPECTRUM II

简单自动化:性能最大化的通用设备平台。

高度自动化、通用和强大:HEUFT SPECTRUM II能够确保在线检测过程中最优化的检测和可靠的操作,以持续保障产品质量和生产线效率。高度自动化及多重处理能力的跨系统控制单元用于不同模块、系统和应用。无需人工干预就可以进行瓶型和结构更换。通用平台独一无二的人机界面是不言自明的,有效地节约了人力资源。内部研发的新一代硬件和软件以及具有前瞻性的网络连接能够达到最大的计算机处理能力和实时数据传输。结论就是:有目的地产品追踪、检测和剔除过程中能达到最大精度。

Fullscreen

HEUFT reflexx A.I.

只需识别更多: 人工智能实时图像处理。

自 2010 年以来,我们自主开发的图像处理技术已经掌握了用于目标对象分类的机器学习这一人工智能学科!从那时起,它已经学会了很多:智能过滤器可以区分容器上的水滴和玻璃中的气泡,甚至可以识别隐藏在 ACL 或浮雕后面的微小缺陷。HEUFT reflexx A.I. 现在还使用了深度学习技术!

经过适当训练的神经网络可用于去噪 X 射线图像或在结构化产品中发现危险异物,并将其与形状、大小和密度极其相似的良好物体可靠地区分开来。通过真正的人工智能,我们自主研发和生产的硬件和软件再次提高了检测的可靠性,并将错误剔除率降至最低。智能图像处理可直接集成到 HEUFT reflexx A.I. 相机中,该相机由公司内部开发,可直接实时处理和评估自身图像,并将自适应图像分析提升到最高水平。

Fullscreen

HEUFT NaVi

轻松知道该怎么做:不言自明的试听用户指南。

直观、独特和试听:无需为了可靠操作HEUFT SPECTRUM II系统而实现学习。HEUFT NaVi用户指南是不言自明的,能够分别一步步地支持用户。带有用户相关权限的RFID登录系统提供了一个概述,使得每个用户的工作都变得简单轻松:用于能在清晰排版的触摸屏用户界面上看到他真正所需要的,通过一个平面菜单结构,综合的教程和精确的辅助工具以最佳的满足他的要求。在这个过程中,他将受到虚拟助理的支持。她会与其说话,并详细地跟他说明何时何地做什么。有目的地关注重点:试听的HEUFT NaVi用户指南使得可靠地操作HEUFT系统变得轻松简单!

Fullscreen

HEUFT checkPoints

简单地查看哪里需要做什么:无故障定位。

清晰、直接和有目的性:用户可以在需要人工干预的情况下立即处理这一罕见情况。因为除了HEUFT NaVi提供的试听信息,醒目的HEUFT checkPoints一下便能马上清晰准确地判断何时必须着手采取行动。万一出现最糟的情况,橙色标签不仅在触摸屏上,同时也在各个部件上闪烁。它的位置不需要长时间搜索。这节省了人力资源,缩短了停机时间从而增加了生产力。

网络技术

全面联网:在线连接以提高效率和质量。

信息实时传输,生产数据采集,线路分析和远程维护:联网就是答案!HEUFT系统拥有前瞻性的网络界面(千兆以太网和TCP / IP)用于通过网络和数据库界面(SQL / DDE)进行在线连接,以通过非常快速和简单的工作流程达到最高的生产线效率和最优的质量管理。因此,可实现全网络可用生产数据、交班记录、生产力错误和HACCP限值分析。结论是:尽早发现质量及效率问题。防火墙能保护与HEUFT TeleService的直接连接以实现全天候提供可靠的远程服务。

HEUFT rejector

剔除错误的产品:适合所有箱子的剔除器。

HEUFT pusher 剔除系统完美适合缺陷空罐的剔除,甚至应用在在高速线上。

-

有效地保护因灌装机/封装机系统的阻塞而造成的生产损失

-

可持续地保护终端产品的完整性和质量

-

现代化的HEUFT SPECTRUM II 控制单元能够在跟踪、检测和剔除容器时实现全面自动化和更高的精确度

-

HEUFT reflexx A.I 高性能图形处理系统保证最大的检测可靠性

-

带有视听辅助的全自动瓶型更换

-

可靠地剔除缺陷容器包含剔除确认

-

由于模块化系统设计可以简单地进行升级和翻新

-

独特简洁的外形尺寸

-

性能范围 ——最高可达144,000个空罐/小时