REQUEST

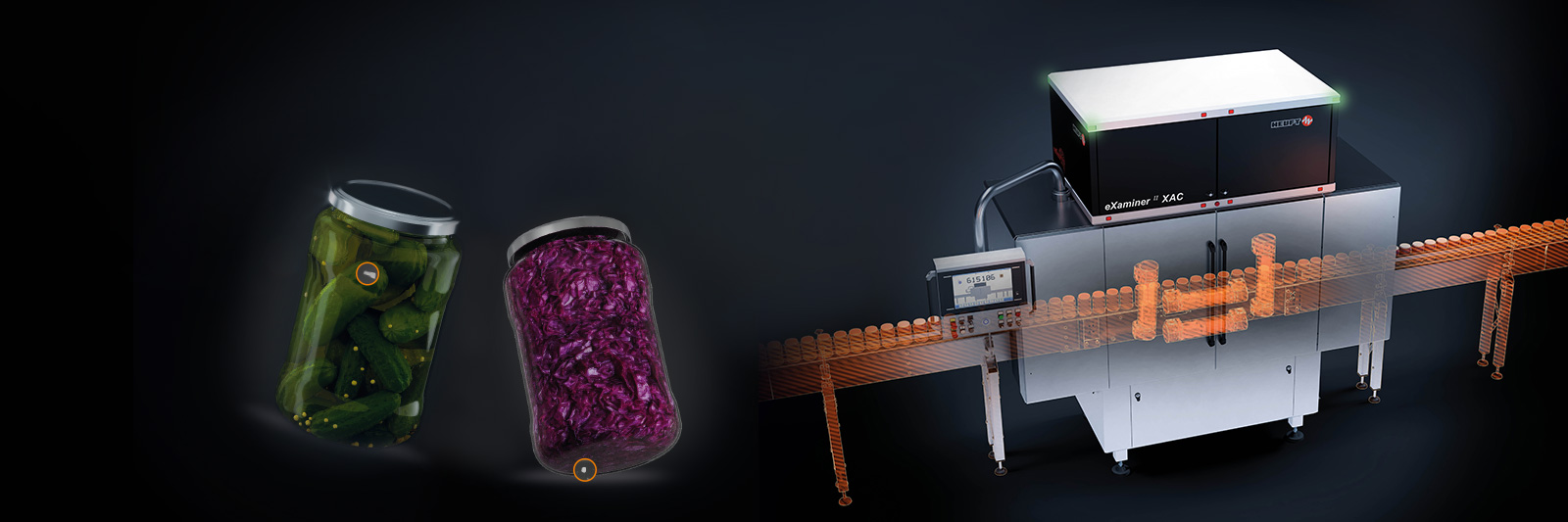

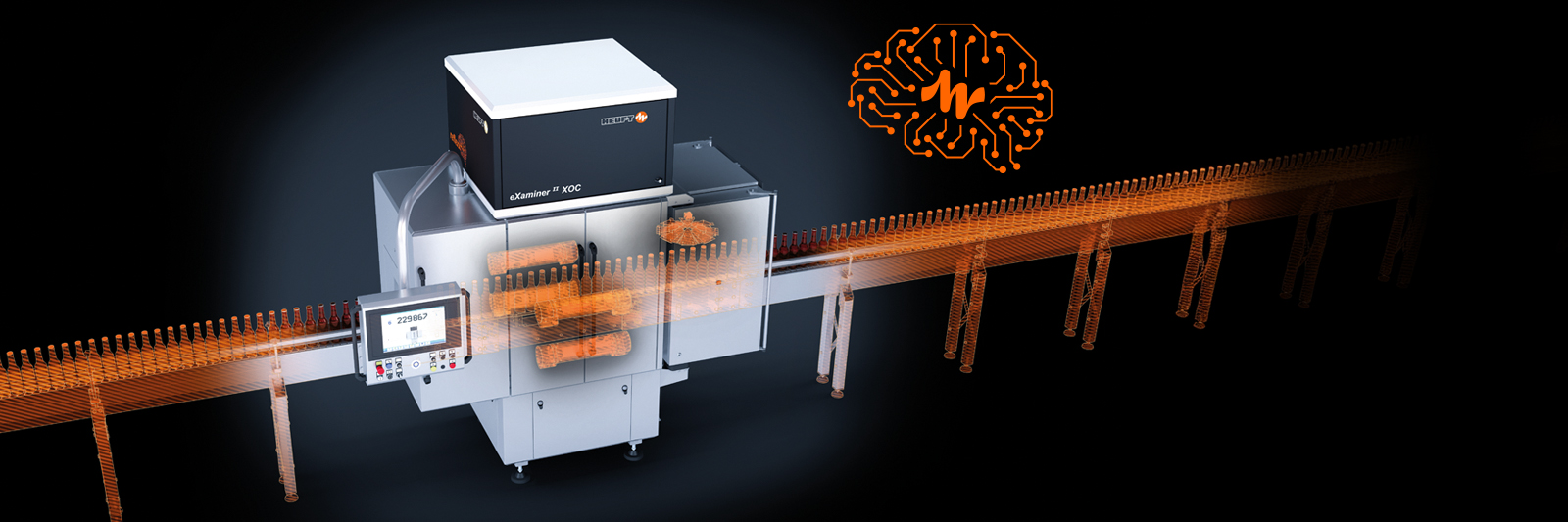

HEUFT is SYSTEMTECHNIK

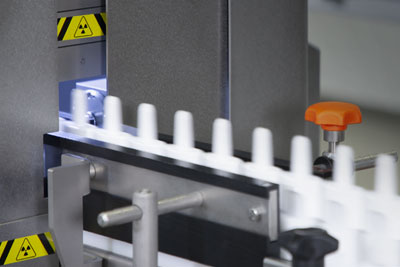

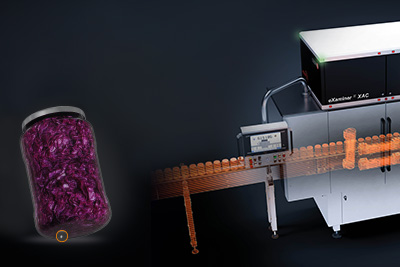

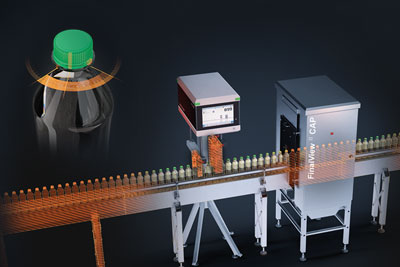

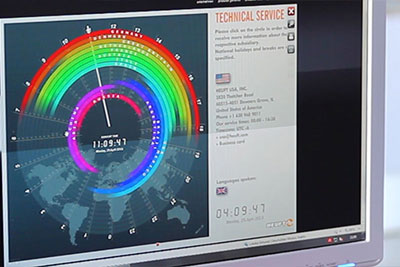

Quality, safety and efficiency: this is what matters when filling and packaging beverages, food and pharmaceuticals! The modular solutions from HEUFT SYSTEMTECHNIK GMBH put these key factors into practice simply and effectively. They ensure, during maximum productivity, that only perfect products reach the market.