On the trail of leaks!

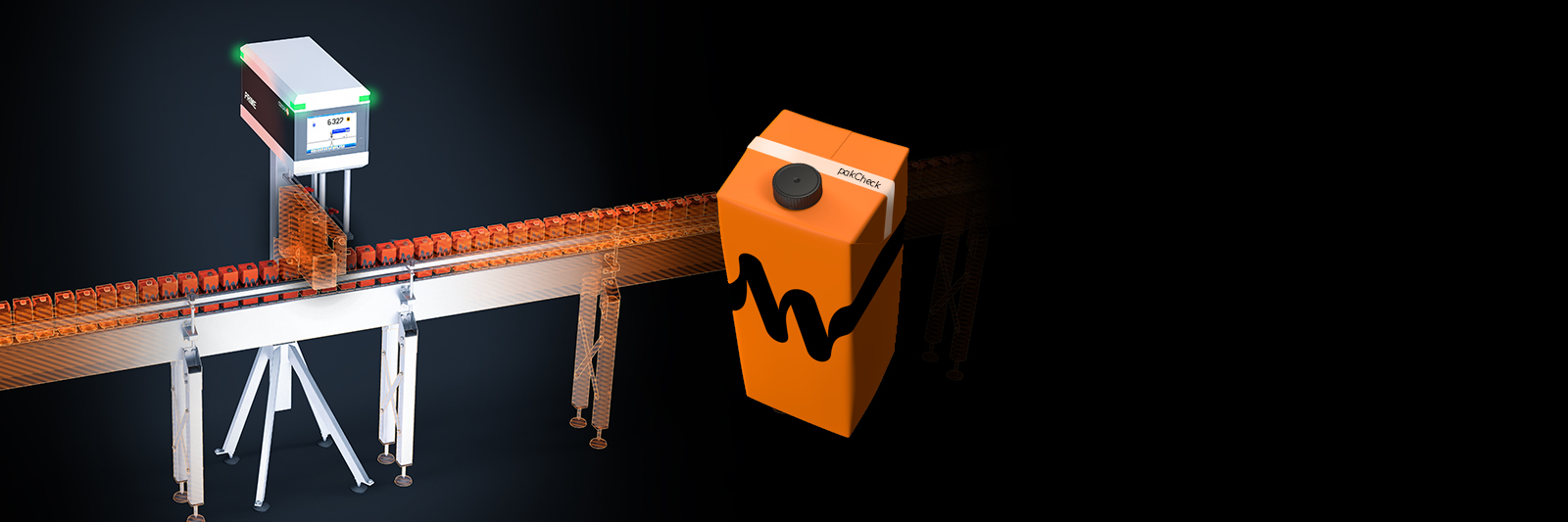

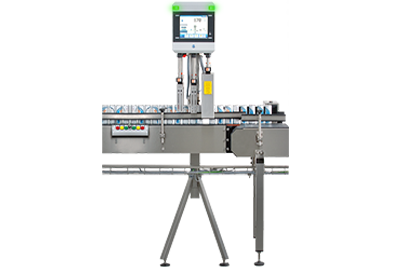

With new pakCheck technology, the HEUFT PRIME examines freshly filled beverage cartons and detects more than just leakages. This will be presented for the first time at drinktec stand B4 121/321.

Unbreakable, opaque, extremely light, simple to stack, transport and store and increasingly recyclable: beverage cartons that have been steam-cleaned and hot-filled have many advantages!

Even when not cooled, liquid contents such as fruit juice or UHT milk remain fresh and edible for a long time. Provided, they are stable and leakproof. The new pakCheck technology for the HEUFT PRIME full container check examines this and more immediately after the block-shaped cardboard composite packaging has been filled – contactlessly, with clever sensor technology and intelligent optics!

Find leaks!

Even micro-leaks are reliably detected in-line by the precise profile measurement of each individual package. This is because leaking cartons suck in air and thus change their dimensions. Several optical sensors check them with millimetre precision and register this. Even the smallest deviations are revealed in this way – and thus leaks which cannot be seen with the naked eye. An X-ray fill level check optimises the result by registering the product loss within the beverage carton caused by packaging leaks.

The presence, integrity, colour and position of the closures are also checked during the same operation. Our intelligent HEUFT reflexx A.I. camera in a top-down arrangement detects non-brand cap colours just as reliably as closures that are not in the right place. This prevents packages from reaching the market that cannot be opened because the lid is not positioned over the pre-perforated membrane. The modular design of the HEUFT PRIME offers a high degree of flexibility for the use of the HEUFT camera, enabling it to check additional quality criteria: Incorrectly glued and thus protruding carton flaps, which can cause faults in the packer, are detected just as reliably as incorrect proportions in the overlap area of the seal seam, which can cause leaks in the beverage carton further down the line.

Verify the BBD!

At the same time the smart camera developed and produced in-house is used to check whether the best-before date is actually present, legible and correct. The reading and verification of the BBD is reliably successful even on high-speed lines where up to 72,000 beverage cartons are filled per hour.

Incorrectly coded, not securely sealed and leaking packaging is clearly identified and reliably removed from circulation – with proven rejection systems such as our HEUFT DELTA-FW flow rejector. The risk of incorrectly labelled beverage cartons with prematurely spoiled contents reaching the market is thus averted as is the risk of contamination from leaking contents.

The HEUFT PRIME with new pakCheck technology will be publicly unveiled at drinktec 2025 at stand B4 121/321 at the Munich Exhibition Centre!