Inspection of returned crates

HEUFT logic II LR

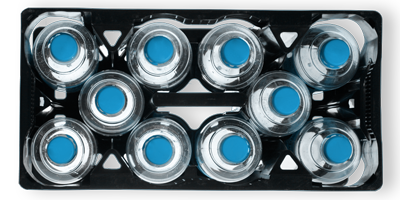

Sorting out non-brand bottles and establishing brand purity: the inspection of bottle crates.

The HEUFT logic II LR empty container inspection system ensures that non-brand, contaminated, and damaged bottles and warped crates do not enter production. The integrated majority detection controls the maximum share of these. Therefore the HEUFT logic II LR optimises line efficiency and reduces production costs sustainably.

Top-down inspection

Ensuring unpacking suitability and safety: checking the compartments and the handling grips.

Foreign objects, top-down bottles and faulty handgrip areas: the HEUFT logic II LR finds returned returnable bottle crates with such faults reliably. It checks their complete insides from above using the powerful HEUFT reflexx A.I. camera for this.

Read more...

Each individual compartment is examined so that crates containing lying containers, top-down bottles or foreign objects are clearly identified and specifically rejected. This ensures the unpacking suitability of the crate. The detection of missing or broken handling grips prevents the risk of injuries. Thus the HEUFT logic II LR upholds the efficiency of the complete line as well as product safety.

Fullscreen

Closure, shape and colour check

Finding non-brand bottles: identifying mixed up crates.

Correct brand, safe and efficient: the HEUFT logic II LR identifies mixed up crates and therefore protects against standstills, bottlenecks and productivity losses.

Read more...

Intelligent evaluation methods detect closures and find bottles of the wrong color. The empty container inspector even reliably distinguishes between different types of swing-top bottles – regardless of whether their closures are open or still on the bottle. With homogeneous lighting from below and powerful camera technology, it finds bottles of the wrong color. Special HEUFT reflexx A.I. cameras are used to clearly distinguish between glass and PET. The image processing determines the number of non-brand containers and decides whether the crate is rejected based on individually adjustable parameters. This prevents too many non-brand bottles from entering the line and only being removed from circulation by the empty bottle sorting unit or the empty bottle inspector.

Fullscreen

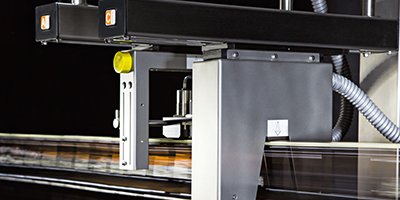

Checking the height proportions

Always at the correct height: profile measurement.

Distorted compartments, foreign objects under the bottle, broken or deformed containers: different factors result in deviating height proportions in the crate. Various factors lead to different height ratios in the box. The HEUFT logic II LR registers them with a 3D scan. The laser can examine different returned crates with empty bottles continuously. It is so flexible in the course of this that it does not have to be readjusted each time for brand and program changes.

Fullscreen

Checking the dimensions

Identifying distorted crates reliably: checking the crate geometry.

Non-brand, faulty and distorted: the HEUFT logic II LR sorts out bottle crates reliably which are not suitable for reuse because they do not belong to the current production program or cannot be unpacked.

Read more...

It determines the length of the diagonals of the crate and uncovers deviations to the target geometry for this. Length, width and height are checked at the same time and compared to stored reference values. The bottle crate in question is rejected before it can enter the line if they differ considerably from the ideal dimensions.

Colour and logo detection

Showing their colours: checking the brand affiliation.

Detecting, comparing and keeping apart: the ever-increasing diversity of brands also affects the outer packaging. Colour and design are an important distinguishing criterion at the Point of Sale (POS). The HEUFT logic II LR checks the colouration of the crate colour and logos in order to make sure that the correct bottles are in the correct crate.

Read more...

It photographs the relevant area using a HEUFT reflexx A.I. camera. The intelligent HEUFT reflexx A.I. image processingevaluates the photograph and compares it in real time with the stored reference sample. The result: a homogeneous supply of the appropriate empty crates.

Combined evaluation of all the measuring results

Calculating the total probability: analysis by means of fuzzy logic.

Combining, comparing and judging: different measuring procedures only produce an optimal result when they are linked with each other. After all not all the crates should be sorted out. Even those with inconclusive, borderline properties can indeed be the correct ones.

Read more...

That is why the fuzzy logic calculates the probability of the individual values determined with regard to brand affiliation and combines them via a complex algorithm into the total probability. Therefore empty crates of the correct brand with negligible deviations do not have to be sorted out. This has a positive effect on the efficiency and productivity of the complete line for returnables.

Complete inspection of empty crates

Detecting deformations, broken handles and shelves, foreign objects in the compartments: empty crate inspection for perfect condition.

A true all-rounder. When positioned behind the can washer, the HEUFT logic II LR inspects empty beverage crates and consistently detects damage and faults that could impair the packer. Thanks to its modular design, it uses the same detection modules that are also used for empty container inspection. It takes individual quality requirements into account. This means that only containers that meet the exact requirements reach the point of sale (PoS).

HEUFT case rejector

Preventing recalls: reliable rejection of faulty crates.

Fast, careful and accurate: highest precision when detecting faults is only effective if the products in question are also removed afterwards. The device either emits a conveyor stop signal or activates the corresponding rejection system, such as the HEUFT maxi-laner, in order to remove incomplete crates from the production flow.

Fullscreen

Monitoraggio del prodotto e auto-test

Andare sul sicuro: tracciare esattamente il prodotto ed eseguire test di funzionamento a scadenza regolare.

Conoscere sempre la posizione esatta di ogni prodotto grazie a un sistema molto preciso di tracciamento. Questo assicura che nessun contenitore venga trascurato dall’ispezione.

Leggi di più...

La verifica integrata di avvenuto scarto controlla che ogni prodotto classificato come difettoso venga effettivamente deviato dal flusso produttivo. Programmi automatici di test assicurano un controllo periodico delle prestazioni di rilevamento. E’ possibile inoltre il monitoraggio continuo tramite rete Ethernet e l’archiviazione a lungo termine dei risultati.

Simple brand changes

Changing automatically: automatic adjustment of the detection units.

Reliable, uncomplicated and easy: the HEUFT logic II LR carries out brand changes without manual intervention. All the parameters are adapted automatically and the height and position of the detection units adjusted by motor. Misadjustments are practically ruled out. This save valuable time and money.

HEUFT SPECTRUM II

Automazione totale: unità di controllo universale per prestazioni ancora più elevate.

Completamente automatica, potente e universale: la famiglia elettronica HEUFT SPECTRUM II assicura la massima affidabilità di rilevamento durante l’ispezione e garantisce la qualità del prodotto e l’efficienza della linea produttiva. Essa è adatta per lavorare con moduli, sistemi e applicazioni diversi e convince grazie al suo elevato grado di automazione.

Leggi di più...

Permette di eseguire cambi formato totalmente automatici, senza alcun intervento manuale. L’interfaccia utente è autoesplicativa e risulta assolutamente intuitiva. In questo modo si attua un grosso risparmio per quanto riguarda le risorse umane. Hardware e software di ultima generazione sono stati sviluppati da HEUFT, mentre connessioni di rete all’avanguardia assicurano la massima potenza di calcolo e di velocità nella trasmissione dati in tempo reale. Il risultato: massima precisione durante il tracciamento, l’ispezione e l’espulsione del prodotto.

Fullscreen

HEUFT reflexx A.I.

Rilevare ancora di più: elaborazione di immagini in tempo reale con l'intelligenza artificiale.

La disciplina AI dell'apprendimento automatico per la classificazione mirata degli oggetti è stata padroneggiata dalla nostra elaborazione di immagini sviluppata in proprio a partire dal 2010! E da allora ha imparato molto: i filtri intelligenti distinguono le gocce d'acqua sul contenitore dalle bolle d'aria nel vetro e permettono persino di identificare piccoli difetti nascosti dietro ACL o rilievi. HEUFT reflexx A.I. ora utilizza anche il deep learning!

Leggi di più...

Le reti neurali opportunamente addestrate vengono utilizzate, ad esempio, per il denoising di immagini a raggi X o per individuare oggetti estranei pericolosi in prodotti strutturati e distinguerli in modo affidabile da oggetti buoni estremamente simili per forma, dimensioni e densità. Grazie a una vera e propria intelligenza artificiale, l'hardware e il software sviluppati e prodotti in proprio aumentano nuovamente l'affidabilità del rilevamento e riducono al minimo il tasso di falsi rifiuti. L'elaborazione intelligente delle immagini può essere integrata direttamente nella telecamera HEUFT reflexx A.I. sviluppata internamente, che elabora e valuta le proprie immagini direttamente in tempo reale e porta l'analisi adattiva delle immagini a un livello superiore.

Fullscreen

HEUFT NaVi

Sapere sempre cosa fare: la guida utente audiovisiva e autoesplicativa.

Intuitiva, audiovisiva e adatta a tutti: non è richiesta alcuna conoscenza precedente per poter lavorare con affidabilità con i sistemi HEUFT SPECTRUM II. L’interfaccia HEUFT NaVi è autoesplicativa e guida l’utente passo per passo.

Leggi di più...

Un sistema di login RFID fornisce accessi riservati per ciascun utente e semplifica decisamente il loro rispettivo lavoro: ogni utente vede solo quello che deve vedere grazie ad un’interfaccia pienamente configurabile, visibile su pannello “touch-screen” e dotata di menù dalla struttura semplice, tutorial integrati e strumenti ausiliari che possono aiutare l’operatore nello svolgimento ottimale dei suoi compiti. Viene in aiuto anche un’assistente virtuale, la quale parla all’utente e gli spiega dove, come e quando intervenire. Concentrata sullo scopo finale e sugli aspetti essenziali – l’interfaccia utente audiovisiva HEUFT NaVi rende il lavoro con i sistemi HEUFT affidabile ed estremamente semplice!

Fullscreen

HEUFT checkPoints

Vedere chiaramente dove intervenire: localizzazione a prova di errori.

Chiari, diretti e risolutivi: l’utente può uscire indenne dalle rare occasioni in cui viene richiesto il suo intervento manuale. Questo perché gli HEUFT checkPoints, in aggiunta alle informazioni audiovisive fornite dall’HEUFT NaVi, rendono visibile a colpo d’occhio quando è necessario intervenire manualmente.

Leggi di più ...

Le etichette arancioni non solo lampeggiano sul pannello operatore ma anche sui rispettivi singoli componenti nel caso si arrivi al peggio. L’anomalia viene localizzata facilmente, senza perdere tempo in lunghe ricerche. Tutto ciò comporta un notevole risparmio di tempo e di risorse umane, riduce i fermi di produzione e aumenta la produttività generale della linea.

Tecnologie di rete

Tutto in rete: essere “online” per far crescere efficienza e qualità.

Trasmissione di informazioni in tempo reale, acquisizione dei dati di produzione, analisi della linea e manutenzione da remoto: la rete è la risposta!

Leggi di più...

I sistemi HEUFT sono dotati di interfacce all’avanguardia di rete (Gigabit Ethernet e TCP / IP) e di database (SQL / DDE) per la massima efficienza della linea e del controllo qualità, con flussi di lavoro più veloci e semplificati. Pertanto dati di produzione, registri degli accessi, difetti di produttività e analisi dei valori HACCP sono disponibili online. Il risultato di tutto questo è una precoce identificazione dei problemi. La connessione ai servizi di HEUFT TeleService è protetta da firewall e garantisce l’assistenza remota 24 ore su 24.

Removing faulty cases:

the right rejector for all cases.

Discharging, rejecting and distributing: HEUFT rejection systems for packaging remove faulty crates, cardboard boxes, trays or shrink wrap packages reliably from the production flow. They achieve maximum performance optimally matched to their respective task with regard to precision and carefulness.

- ensuring the brand purity, unpacking suitability and quality of returned crates with empty bottles

- easy automatic brand changeover

- compact, easy to clean construction

- modular system in order to fulfil the customer's specific requirements optimally

- high processing speedreal-time image processing for maximum inspection quality with minimal false rejection rate

- intelligent combination of 3D lasers and HEUFT reflexx A.I. cameras