Conveyor control system

HEUFT synchron TXI

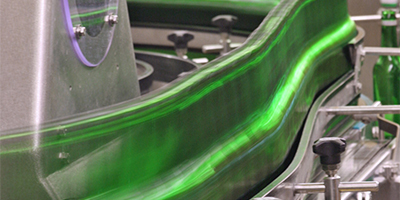

Standstills ruled out: a conveyor control system with vision.

The overall efficiency of your filling line leaves much to be desired even though the individual machines function optimally? Then there is probably a problem with the container flow between the devices. The HEUFT synchron conveyor control system puts things right. It accelerates the containers smoothly, closes gaps, optimises the conveyor speed and increases the efficiency of the complete line.

Conveyor control system

Closing gaps and preventing jams: regulating the conveyor speed.

Without pressure, gentle and efficient: the HEUFT synchron TXI implements a regulated bottle flow in real time. The conveyor control system always knows about its current status in an intelligent and foresighted way. Thus it can close gaps gently and prevent jams in good time.

Read more...

It regulates the conveyor speed harmoniously and accelerates the containers smoothly and without impact pressure for this. This protects the bottles and conveyors, reduces noise and increases the efficiency of the complete line.

Fullscreen

Electronic block operation

Supplying master machines continuously: single-lane blocking and laning.

Rinser, filler and labeller: the bottles have to be one behind the other without gaps before they enter master machines such as these. The HEUFT synchron TXI considers the single-lane line sections as a whole in order to ensure this.

Read more...

It follows the individual positions of the bottles, links the calculated results and in this way achieves a carefully controlled bottle flow. Gaps are closed gently without creating new ones. Whether the effective electronic blocking of two master machines or the dynamic laning of the bottles: the HEUFT synchron TXI even copes with demanding tasks effortlessly.

Fullscreen

Regulating the buffer sections

Avoiding standstills: controlling the mass transport.

Foresighted, in good time and effective: the HEUFT synchron TXI stops malfunctions in the mass transport before they can spread to the single-lane line sector. It controls the buffer sections with vision. This effectively prevents blockages and standstills of the master machines.

Read more...

Optimal operating conditions are the result when this is integrated into the control system. For example specifically regulating the speed of the washing machine not only avoids stops but also prevents the spreading of lye. This safeguards the product quality sustainably. The bottles are transported smoothly and without pressure being applied to them in the buffer sections controlled by the HEUFT synchron TXI. Gaps in the mass transport are closed gently. In this way full utilisation is always guaranteed.

Fullscreen

Container laning

Dividing up the bottle flow: reliable container distribution.

Controlled, gentle and quiet: the HEUFT traxx and HEUFT XY laning systems, which are perfectly coordinated with the conveyor control system, take over the bottles which have been precisely laned onto up to four lanes by the HEUFT synchron TXI. They even take unstable empty and full bottles to the correct lane in an upright position and without falling over. And this occurs with minimum noise emission.

Fullscreen

HEUFT SPECTRUM TX

Controlling centrally: one platform for all requirements.

Precise, network-compatible and cross-system: the HEUFT SPECTRUM TX forms the basis for different technologies, modules and functions. The devices of the generation of the same name can be exactly adapted to individual requirements on site and retrofitted at any time due to this universal platform.

Read more...

A cross-system component equality of 70 per cent ensures a high availability of spare parts. The central HEUFT SPECTRUM TX control unit creates a high level of precision during continuous product tracking and quality assurance due to its multiprocessing capability. A future-proof network connection ensures reliable remote maintenance and production data acquisition for optimum efficiency and productivity. In-house developed hardware and software and its own operating system ensure computing power and offer no opportunity for viruses or malware.

HEUFT PILOT

Lavorare con I sistemi HEUFT in modo affidabile: interfaccia utente grafica e pratica.

Chiara, utile e precisa: l’interfaccia grafica HEUFT PILOT è corredata di menù multilingue facili da capire e di diversi strumenti ausiliari. Pertanto l’utilizzo dei sistemi HEUFT SPECTRUM TX non è difficoltoso.

Leggi di più...

Importanti informazioni e chiari messaggi di errore forniscono all’utente un supporto specifico. Questo evita regolazioni sbagliate e riduce i tempi di fermo,ad esempio per i cambi formato. Livelli operatore protetti da password sono configurati in base all’area di competenza dell’operatore, cosa che contribuisce alla facilità d’usa del dispositivo. Sono inclusi: un completo manuale online e uno strumento per identificare e ordinare le parti di ricambio in modo semplice.

Tecnologie di rete

Tutto in rete: essere “online” per far crescere efficienza e qualità.

Trasmissione di informazioni in tempo reale, acquisizione dei dati di produzione, analisi della linea e manutenzione da remoto: la rete è la risposta!

Leggi di più...

I sistemi HEUFT sono dotati di interfacce all’avanguardia di rete (Gigabit Ethernet e TCP / IP) e di database (SQL / DDE) per la massima efficienza della linea e del controllo qualità, con flussi di lavoro più veloci e semplificati. Pertanto dati di produzione, registri degli accessi, difetti di produttività e analisi dei valori HACCP sono disponibili online. Il risultato di tutto questo è una precoce identificazione dei problemi. La connessione ai servizi di HEUFT TeleService è protetta da firewall e garantisce l’assistenza remota 24 ore su 24.

- homogeneous bottle flow without gaps or jams

- continuous supply to the master machines

- optimised efficiency for the complete filling line

- effective protection against defects to the bottles and avoidance of noise along the line due to smooth transport and combining without impact pressure

- fully compatible with existing PLC systems

- turnkey solutions for line optimisation including competent project planning