Line optimisation, part 2: Empties under control

For an efficient sorting of empty bottles in a returnable line, you need the appropriate equipment. And the right know-how for a consistent sorting concept with an optimally coordinated line layout. HEUFT offers all this from one source! Part 2 of our new series on the subject of line optimisation explains the possibilities.

Shortage of empties. This keyword has been circulating in the German newspapers again and again lately. Beverage producers appeal to consumers to return their empty returnable bottles quickly. At the same time, demands on reusable bottlers to abandon individual bottles are becoming louder and louder. A comeback of collectively used pool containers is called for. But even with the exclusive use of standard bottles, there are still so many different types, formats and colours that mixing and sorting efforts remain high and acute shortages of empties continue to threaten to impair the efficiency and productivity of entire bottling lines.

In order to counter this, many a returnable bottling line is outsourcing the sorting of empties: external service providers are to take care of this outside the company's own premises and ensure that only those empty bottles are returned to the bottling plant that are actually transported there. But this means losing flexibility and being dependent not only on the currently longer delivery times for new glass but also on those of the respective sorting provider for returning empties.

Full control in sorting empties

If you want to remain spontaneous and reactive and keep control, it is better to sort the bottles yourself on site in order to rid your production stream of foreign bottles but also of your own bottles of the wrong format. And with as little manual effort as possible. This is not possible without a consistent sorting concept with targeted adaptation of the line layout, in order to be able to convey the empties carefully even when space is limited, to discharge them securely while standing upright and to distribute them precisely along many routes. Also essential: a highly automated, state-of-the-art empty bottle sorting system. At HEUFT returnable bottlers get all this from a single source:

Thanks to decades of experience and the corresponding know-how for optimising the layout of complete lines, the suitable HEUFT conveyor belts and HEUFT synchron conveyor control systems as well as up-to-date equipment for sorting out and safely rejecting foreign and faulty bottles our team develops the suitable sorting concept for the individual application on site – and puts it into practice in a perfect fit.

Protection against line and production stops

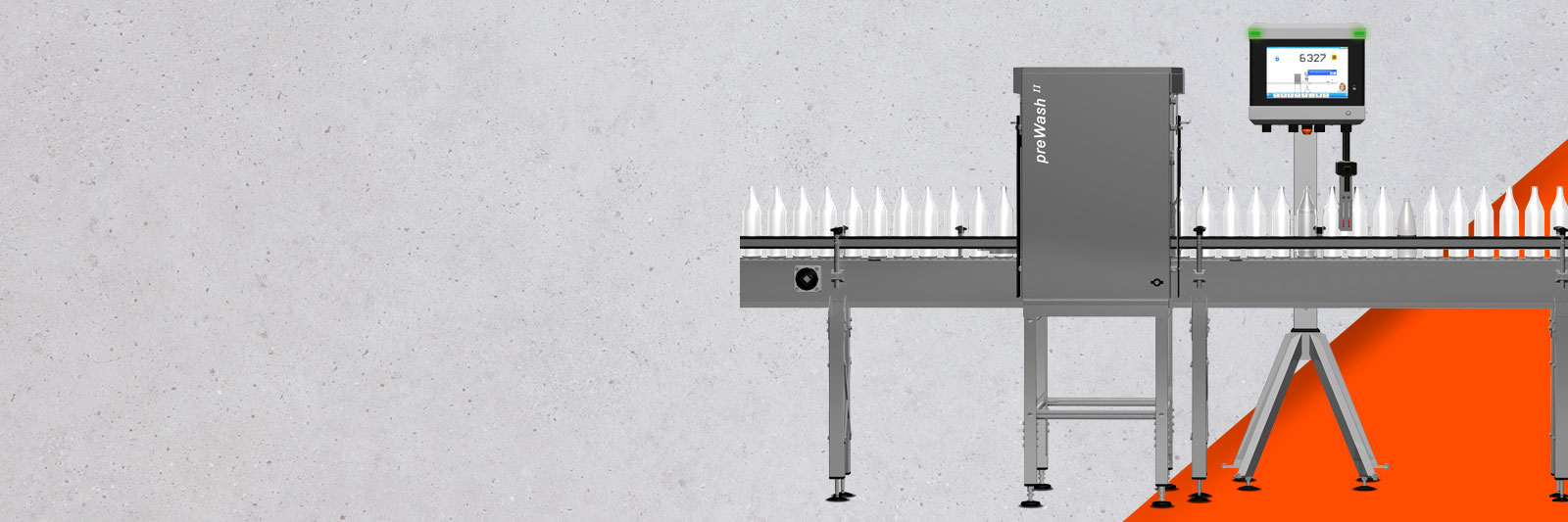

The HEUFT SPECTRUM II SX empty bottle sorting system with the innovative HEUFT preWash II module is the linchpin of this. Before this an infeed check removes the causes of faults such as bottles which are lying down, broken or standing crookedly and which cannot be conveyed upright. Efficient sorting of empty bottles stands and falls with the upright rejection of foreign and faulty bottles. Otherwise, containers that are unstable in shape and fall over lead to backlogs, blockages and line standstills.

Unwanted production stops are also imminent if the washing machine breaks down and heavily contaminated bottles impair the caustic concentration to such an extent that cleaning performance is no longer guaranteed. 20 to 30 millilitres of lye in a single bottle are enough to cause this. That's why a new residual-liquid detection unit now also distinguishes between colours, so that, for example, bottles that still contain yellowish beer residue are passed through as washable, while those with red diesel or green lye are rejected immediately. Because bottles contaminated with hazardous liquids can thus also be reliably identified, the detection unit protects the bottling line staff from dangerous chemical burns.

Sorting before bottle cleaning

However, the main features of the new HEUFT preWash II module in the HEUFT SPECTRUM II SX empty bottle sorting system include on the one hand the contour inspection using the transmitted light method which only lets containers through which are in the correct format currently being handled and at the same time also detects and rejects those of these which are highly soiled, scuffed or contaminated with foreign objects. In order to reliably identify non-brand ACL labels and embossings and to use them as a criterion for sorting out foreign bottles, it also implements a high-resolution colour camera inspection in reflected light. Even glue residues from self-adhesive labels that cannot be removed in the washing machine are now reliably detectable. Containers that stick together and might fall over as a result, disrupting the production flow further down the line to the empty bottle inspector, are rejected in good time beforehand.

Of course all the HEUFT empty bottle inspectors would also detect such faults. But for refillable bottlers who want to keep their line performance as constant as possible this would then already be too late. The only way to keep the performance stable after washing is to sort out the affected empty bottles beforehand. It would be just as inefficient to wash foreign bottles. As a rule a HEUFT SPECTRUM II SX is therefore ideally placed in front of the bottle washer in order to differentiate between glass and PET bottles for example. With several rejection systems the upright rejection is even fault-specific: PET bottles which do not belong to the portfolio are diverted upright by the first HEUFT LAMBDA-K rejection system for example, foreign glass bottles by the second, pool bottles of the wrong size by the third and heavily soiled ones by the fourth.

Gapless supply of empty bottle inspector and filler

If containers of different sizes were sorted out after the washing machine, at the infeed check of the empty bottle inspector, there would be undesirable gaps in the production flow. To close them and ensure a gapless stream, the line would have to be stressed at high speed. The same applies to soiled or contaminated empties, which are only detected in the inspector itself and then rejected: To ensure a gapless supply to the filler as a master machine in the further course, the belt speed must be unnecessarily increased here as well.

After all, in order to reliably sort bottles that are not suitable for the current filling process onto different lanes and paths in a space-saving manner, it is essential to have the right mechanical settings. This also applies in particular when it is a matter of changing the type and format and, for example, changing over from the 0.5-litre to the 0.33-litre production bottle. This works fully automatically with the HEUFT SPECTRUM II SX; the detection and rejection modules adapt to the changed format automatically.

Conclusion: a complete empty container sorting concept from a single source

Together with good ideas for an optimised line layout and the right conveyors, belts, rejection and distribution systems, a consistent, effective and efficient sorting concept can be developed and implemented directly at the filler's premises, even when space is limited. This can also include the integration of a HEUFT LX empty crate inspection which, among other things, ensures that the unpacker only takes empty bottles from his own portfolio out of the returned crates so that the HEUFT SPECTRUM II SX only has to sort out those which are too dirty, stuck together or contaminated or whose format does not match the type currently being handled.

HEUFT thus plans and realises the optimum concept and the most efficient individual solution for sorting empty containers in the returnable line with a great deal of know-how, decades of field experience and innovative equipment for the most varied on-site conditions and applications.