Simply more possibilities!

More computing power and operational reliability, more range and detection performance: the highly automated HEUFT eXaminer II XB combines pulsed X-ray technology, only available from us, with innovative full-field image converters as the first system of its kind. In this way it also carries out a continuous top-down inspection of oversized products – and even the parallel examination of two products at once!

Simply detecting foreign objects such as glass splinters, metal pieces or plastic particles as well as product and packaging defects with greater care and precision: the HEUFT eXaminer II XB achieves this! Not only its new head provides considerably more performance for this but also its pulsating heart: based on the highly automated new HEUFT SPECTRUM II device platform the system is equipped with compact full-field image converters for the first time. This makes the unique pulsed X-ray inspection even more powerful.

The resolution and the sensitive detection surface have increased significantly and therefore packaged or unpackaged food in larger formats can now also be inspected completely and with high precision. Even the parallel examination of two products at once is possible with the new HEUFT eXaminer II XB. This increases its maximum throughput up to 2,400 products per minute.

X-ray strobes for optimal detection reliability

The extremely clear detection pictures remain free of distortions and aberrations. At the same time the X-ray parameters adapted to the new technology reduce the already unequalled low radiation. In contrast to the conventional scan it is emitted as X-ray flashes which only last a thousandth of a second. And only then when there is really something to be inspected. This flashing prevents motion blurs which can impair the detection reliability particularly during high-speed operation. In addition it makes a static top-down inspection possible: the product can also be precisely examined even when the conveyor is not moving e.g. for internal quality assurance purposes. Furthermore the smart multiple flash option carries out a continuous inspection of particularly long products.

This pulsed X-ray technology, exclusively available from HEUFT, makes the use of the compact full-field image converters possible in the first place. The X-ray generators and the high-voltage components have also been sustainably optimised. As a result there is more room and flexibility when adapting the conveyor for the precise inspection of products of different heights. Cooling is no longer required and therefore the risk of product contamination by possible coolant leaks is ruled out. The easy to replace conveyor automatically adapts itself to the respective product weight – the mechanical drive has been perfected! This reduces the need for manual intervention and simplifies the maintenance of the space-saving and easy to clean system.

Simply more performance!

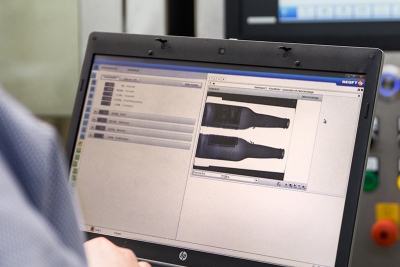

The considerably increased degree of automation and computing power of its HEUFT SPECTRUM II head with the self-explanatory HEUFT NaVi user guidance make the resource efficient, tamper-free operation of the new HEUFT eXaminer II XB simply easy. The integrated HEUFT reflexx² real-time image processing system clearly differentiates between harmless product inhomogeneities and critical foreign objects or defects. And its new pulsating heart increases the range, flexibility and detection reliability during a careful top-down inspection.