More and more possibilities

HEUFT product manager Anton Diehl recently explained the state of the art regarding digitisation when inspecting foreign objects and already gave a glimpse into the not-so-distant future at the LBMTD meetup in Butzbach, Germany.

Has digitisation been well received by the industry? And if so: how advanced is it, what are the real benefits and what are the next steps? Questions such as these were the focus of the LBMTD meetup, to which the Netzwerk Lebensmitteltechnik Deutschland (Food Technology Network Germany) had invited almost 100 representatives of important food manufacturers, suppliers and educational institutions to Butzbach in Hesse. It soon became obvious: although it still seems to be in its infancy when compared to other branches of industry the so-called digital revolution has already reached the food sector too.

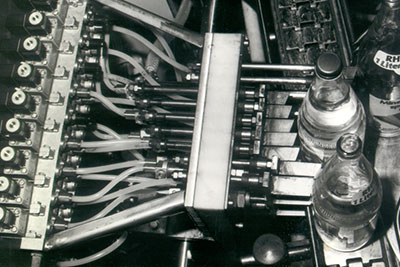

This applies in particular to HEUFT equipment for detecting foreign objects which was presented by product manager Anton Diehl during his best practice presentation: his employer had already started to develop his own quality inspection equipment controlled by microprocessors more than 40 years ago. The rapidly increasing computing power of the microchip, on which all the necessary components are combined, is one of the three main drivers which has continued to advance the megatrend of the digital transformation since then. Therefore the in-line inspection systems from HEUFT have been implementing increasingly powerful multiprocessing for decades.

More efficiency, flexibility and safety during the filling and packaging process

For the HEUFT product manager networking is the second important driving force behind digitisation. It ensures data exchange between the devices and in addition to comprehensive production data acquisition it also makes, among other things, their remote maintenance and online connection to higher-level MES and ERP systems possible. This results in real-time line analysis with the HEUFT PROFILER for increasing the efficiency and productivity of the entire filling and packaging line, the complete archiving of relevant operating figures as well as the reliable, long-term HACCP documentation of quality data and detection images for a continuous foreign object management.

And the direct connection to production management systems together with the HEUFT RECIPER IT tool also achieves central brand management and changeovers including the fully automatic adaptation of all the detection units. Therefore, says Mr Diehl, more than 20 years after the market launch of the first network-compatible HEUFT systems the wish for a significant increase in "profitability and flexibility during the filling and packaging process with improved quality and safety at the same time" is increasingly being fulfilled. However in this respect it is essential not to leave the human behind: digitisation must be useful to him and actively support him in his duties. This is exactly why new generation HEUFT systems are practically self-explanatory due to the audiovisual HEUFT NaVi user guidance. The innovative hands-free dialog function even makes an efficient voice control possible.

More detection performance due to intelligent real-time image processing

Mr Diehl allocates the third main driver, regarding digitisation when inspecting foreign objects with unique procedures such as the pulsed X-rays available exclusively from HEUFT, to increasingly dynamic and powerful algorithms when processing the data obtained thereby on a software level in particular during real-time image analysis. These have been constantly developed further for the reliable identification of objects with the HEUFT reflexx up to the targeted object classification with the HEUFT reflexx² from purely counting pixels to a grey shades detection. Together with the ever-increasing computing power of the in-house developed hardware even more is becoming possible with the image processing alone – up to a dynamic adaptation to fluctuating material structures so that in the meantime, for example, even deviating base strengths of bottles and jars can be tolerated and compensated in order to identify foreign objects in this area particularly reliably. Each individual container is measured in real time for this.

According to Mr Diehl, the next step will be a teaching in procedure which will enable the image processing software to evaluate structures and objects exactly as if it were a person who thinks for himself. And this again can only be carried out with innovative algorithms as well as more and more computing power. It is therefore really good that HEUFT has developed and continuously expanded both the hardware required for this and the software adapted precisely to it from the outset so that it will continue to keep pace with the increasingly important digitalisation for the filling, packaging and in-line quality assurance of food in the future.