Glass-in-glass detection in full containers: precision and flexibility in confined spaces

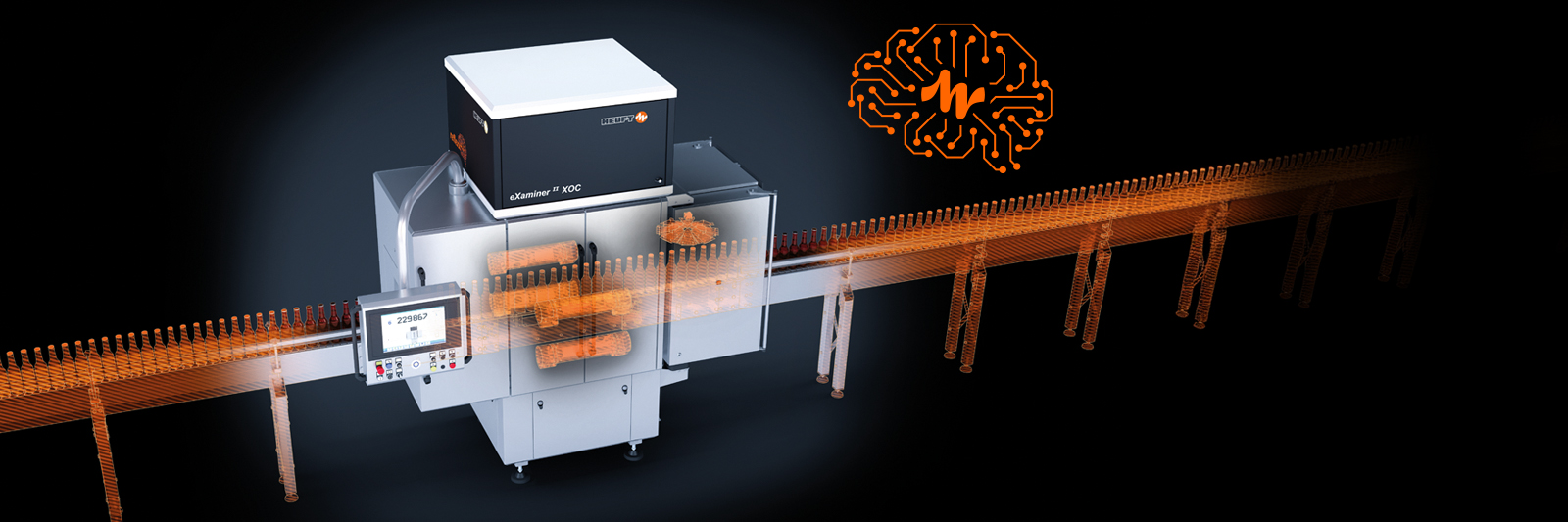

Integrating the full bottle inspector for glass-in-glass detection even where space is limited. HEUFT will be demonstrating how this works at drinktec with a new compact platform for pulsed X-ray inspection at the end of line.

Pulsed X-rays for glass-in-glass detection in full containers has established itself as the state of the art at the end of line. With additional high-performance optics that identify low-density foreign objects in the beverage, the HEUFT eXaminer II XOS is the only one of its kind to offer this. Until now: At drinktec, the inventors of the X-ray flash technology are presenting a new platform as a study, with which the radiometric identification of glass splinters or shell-shaped fractures at the base of freshly filled glass bottles can once again be made significantly more space-saving – the HEUFT eXaminer II XOC. A new development for label-friendly transport of filled glass bottles creates even more flexibility in integration – and at the same time expands the range of container shapes that can be inspected.

Space-saving and flexible integration

For foreign object and glass defect detection, the prototype exhibited for the first time at drinktec only integrates the advanced components for pulsed X-ray inspection with intelligent X-ray image processing. The deliberate omission of optical foreign matter inspection with HEUFT sinker and HEUFT floater reduces the inspection path and thus also the dimensions: in this version, the HEUFT eXaminer II XOC is just about a meter shorter than the HEUFT eXaminer II XOS. This means that it fits into smaller installation spaces at the end of line and can be installed in a space-saving manner not only behind the filler but also behind the labelling machine.

Labels on the bottle do not affect the exceptional detection reliability of pulsed X-ray inspection with AI-supported HEUFT reflexx A.I. X-ray image processing. A specially developed new belt drive transports the bottles through the device in a label-friendly manner and aligns them optimally for X-ray inspection using servo control. To do this, it clamps them not at the body, but further up at the neck, so that the labels remain undamaged and glass-in-glass detection is even possible in non-cylindrical containers.

Simply greater detection power

Even the most compact version of the new platform still offers sufficient space for additional narrow detection modules. This means that, in addition to X-ray-based detection of foreign objects at the bottom of the bottle or shell-shaped fractures at the bottom edge, the trade fair prototype can also perform an all-around inspection of the bottle closures using integrated HEUFT FinalView II CAP technology in the same operation. If, for example, the HEUFT floater is to be integrated in order to recognize transparent film floating in the beverage, this is also possible with only slightly larger dimensions.

The HEUFT eXaminer II XOC thus creates greater flexibility for full container inspection at the end of the line, even in bottling lines where the fully equipped HEUFT eXaminer II XOS does not fit, and achieves HEUFT-level detection reliability there with pulsed X-rays and intelligent X-ray image processing.