Pulsed X-rays, high-performance optics

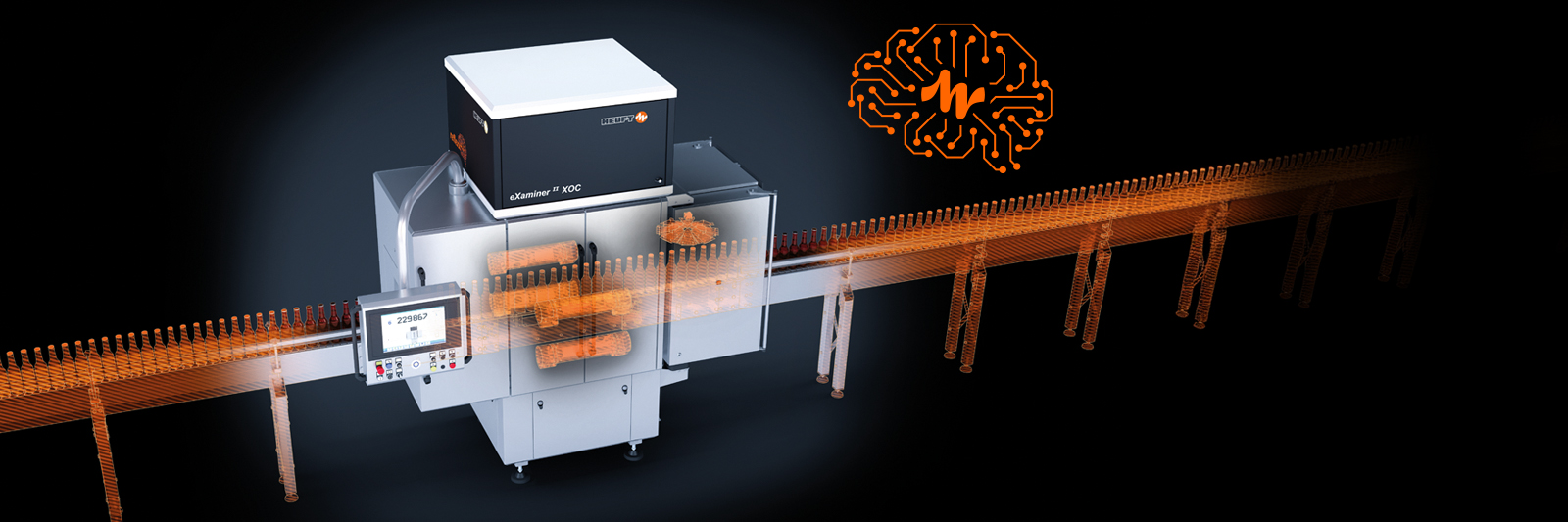

and deep learning!

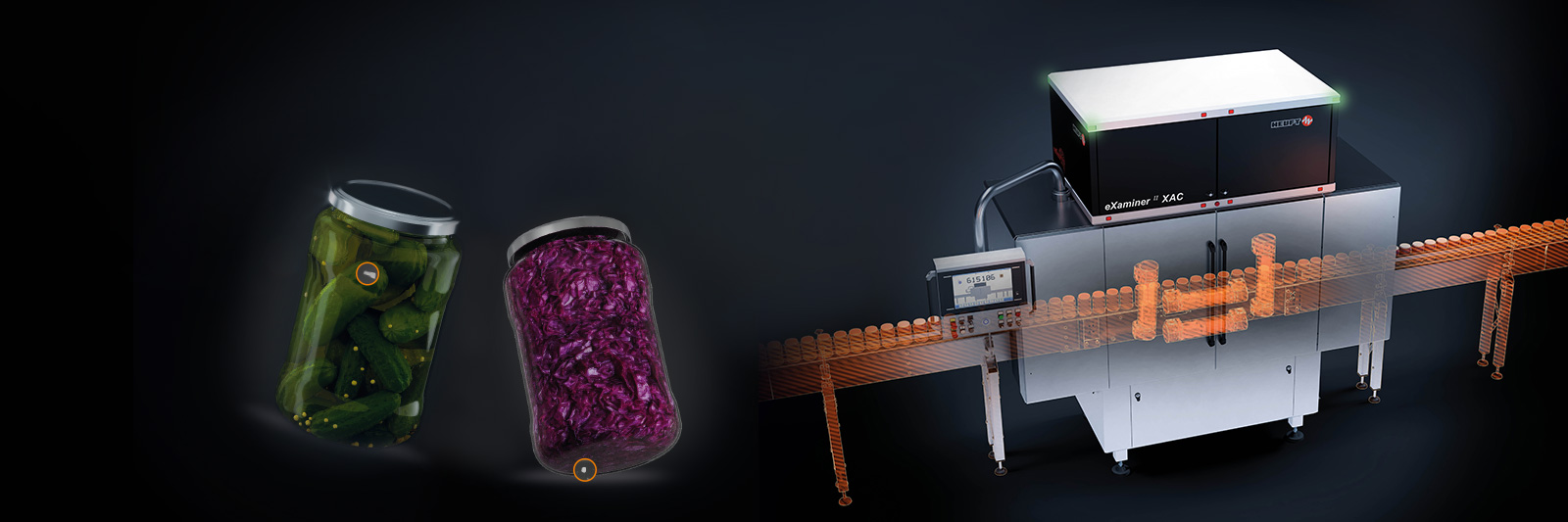

Pulsed X-ray technology with AI-supported X-ray image processing

for improved glass-in-glass detection.HEUFT reflexx A.I. cameras, MCIP

and deep learning for optical empty bottle inspection that goes deeper

and judges more competently: With innovations developed in-house,

the HEUFT InLine II IX once again pushes the boundaries of what

can be detected – while also reducing the false rejection rate!