DIP: Difficult, but not impossible to inspect!

07 January 2026

With conventional methods, it is difficult to check the integrity, safety and functionality of many medicines and primary pharmaceutical packaging in-line. The same applies to medical devices such as prefillable syringes. Fortunately, in many cases there is an alternative to optical quality control of such difficult-to-inspect products (DIP): HEUFT's pulsed X-ray technology. It gently reveals what remains hidden to the human eye and even high-performance cameras.

DIPs include opaque or heavily coloured solutions, powders, pills, tablets in blister packs, concentrated emulsions and suspensions, and lyophilised parenteral products, which are difficult to inspect visually. Difficult container types include non-transparent primary and secondary packaging, but also medical devices such as prefillable syringes, auto-injectors and single-dose dispensers with components that are not fully visible from the outside.

In order to inspect each individual DIP in-line and reveal foreign particles, defects and deficiencies that cannot be seen with the human eye or even with sophisticated camera technology, an alternative is needed that can also X-ray opaque preparations and containers. This can be done with gamma or X-rays. However, the use of such radiometric methods was long considered unsuitable for the manufacturing and packaging process of pharmaceuticals. There was too much concern that the radiation could impair the efficacy and safe usability of the product contained.

Minimal radiation

The pulsed X-ray technology, available exclusively from HEUFT, is a real game changer in this regard. This is because it only emits an X-ray pulse, when necessary, which lasts no more than a thousandth of a second; in up to 99 per cent of the operating time, no radiation is emitted at all. Only in the brief moment when a product to be inspected is in the detection area is such an ‘X-ray flash’ generated electrically. Its maximum intensity is only 0.000015 Gy, which is 7,000 times below the threshold at which irradiated medicinal products must be labelled as such.

The risk of pulsed X-rays impairing the efficacy of active pharmaceutical ingredients (APIs) is correspondingly low; the exposure time is too short and the intensity and dose of the pinprick-like X-ray pulses are too low. Empirical studies, our own in-house tests and over 50 successful installations at pharmaceutical customers have demonstrated this.

Intelligent X-ray image processing

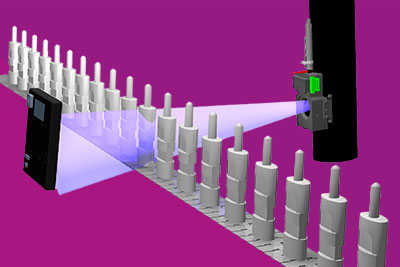

The exposure time during flashing is also extremely short. Unlike with permanently activated line scanning, no motion blur can reduce the clarity of the X-ray images and obscure objects to be identified. The product stream is literally frozen. Streaks and blurred areas, which make it difficult to detect glass particles, metal fragments, defects or incomplete products, are no longer an issue, even at high or fluctuating line speeds.

The deep learning-capable HEUFT reflexx A.I. X-ray image processing system, developed and manufactured in-house, also contributes to the exceptional detection reliability in DIP inspection. It eliminates image noise and artefacts and compensates for thickness variations in the packaging material, among other things, so that a wide variety of objects can be better detected and evaluated. This makes it even easier to distinguish critical errors from harmless deviations.

Precise inspection of medical devices

It is not only foreign particles in DIPs that finally become visible. The same applies to special rubber stoppers that hermetically seal the glass vial containing the life-saving liquid preparation in single-dose dispensers until it is administered, for example, nasally. If they are missing or incorrectly positioned, the HEUFT eXaminer II XS detects this just as reliably as broken or contaminated cartridges, missing or defective actuators or incorrectly aligned cannulas. A single compact X-ray flash module for sidewall inspection is sufficient to make the entire interior of such opaque medical devices visible.

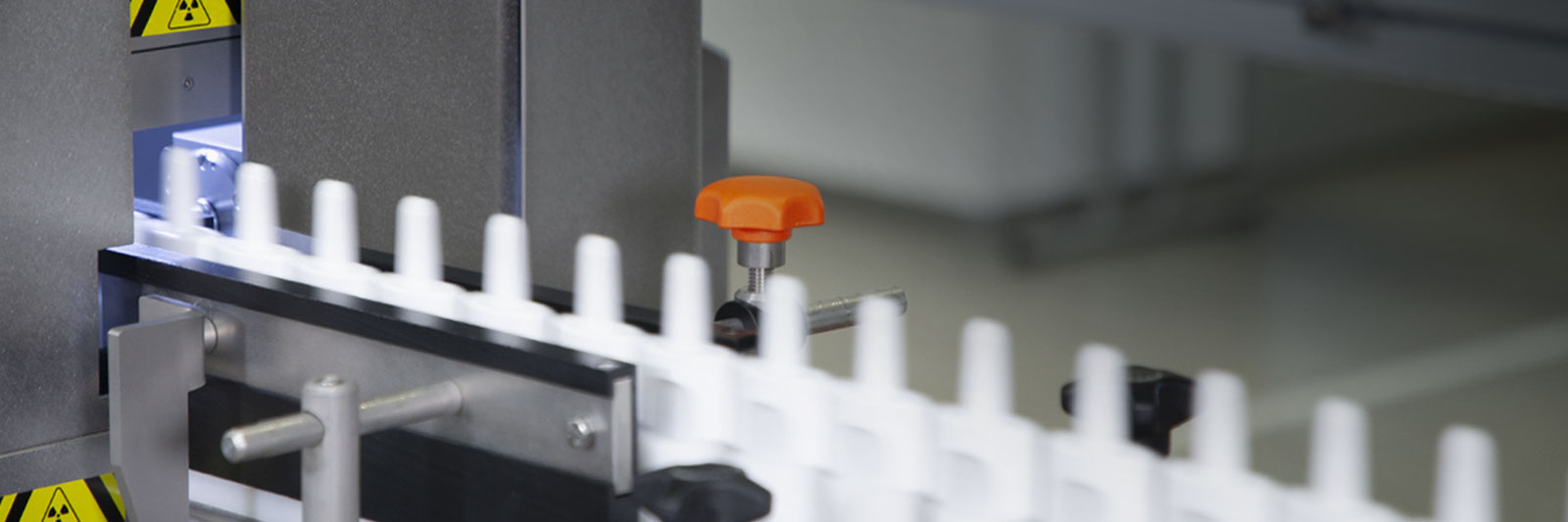

For pulsed X-ray inspection in the assembly and packaging process of prefilled syringes, two of these modules are ideally used in the HEUFT Syringer to reliably identify bent injection needles. Prefilled syringes with missing needle protection caps or caps that have been punctured or pierced by the cannula are also reliably detected.

Always the right perspective

Top-down, bottom-up, from the side and even overlapping for 3D back confirmation during particle detection: the compact X-ray flash modules can be positioned flexibly and easily integrated into linear HEUFT inspection systems to achieve the best possible results in every application. From above, for example, the HEUFT eXaminer II XB is best suited for identifying missing or crumbled tablets in blister packs, whereas the completeness of all blister strips in the secondary packaging can best be checked from the side with the HEUFT eXaminer II XS. This also applies to the detection of foreign objects in vials and other primary packaging made of glass that contain emulsions, suspensions, powders, granulates or lyophilised products.

No complex protective measures are required to integrate appropriately equipped HEUFT X-ray systems with type approval into pharmaceutical lines. The emission of ionising radiation is so low that the securely encapsulated X-ray modules can even be used without any problems in hygienically sensitive laminar flow areas.

All this makes pulsed X-ray with HEUFT reflexx A.I. X-ray image processing ideal for 100% verification of the integrity, safety, completeness and functionality of medicines and packaging materials that were previously considered difficult to inspect. During the assembly, installation and final inspection of medical devices for the precise administration of active ingredients, as well as during the in-line inspection of opaque preparations and packaging materials, it reveals what remains hidden with conventional visual methods. What was previously invisible becomes visible!

.