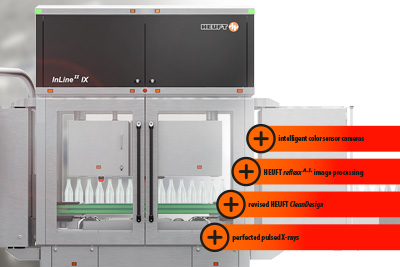

drinktec: Deep learning for empty bottle inspection!

Ensure truly comprehensive optical all-surface empty bottle inspection at all times. Intelligently enhance performance, sensitivity and judgement in the detection of faults with pre-trained deep learning AI. Enable artificial intelligence to make the previously invisible visible. Minimise the false rejection rate and sustainably increase the efficiency of entire filling lines. HEUFT reflexx A.I. and MCIP now make this possible!

Even the best AI can only detect what is in view. To make challenging types of faults visible, you need the right imaging procedures. The more information an image contains, the broader the range of safety and quality defects that can actually be detected, evaluated and classified.

Intelligent MCIP sidewall inspection

uperior optics are particularly important here: integrated directly into intelligent HEUFT reflexx A.I. cameras, the in-house developed Multi Colour Image Processing (MCIP) always shows the bottle walls in the right light. To achieve this, different illumination principles, such as bright and dark field illumination in reflected and transmitted light, are combined. This is done in different colours in order to separate the resulting information spectrally and to calculate the individual colour channels with each other in such a way that a wide variety of characteristics can be identified:

Glass breakouts and chipping in the thread and underchip area can be seen across the entire surface during inspection of the upper sidewalls thanks to structured MCIP colour illumination, even if the containers are made of white glass. Harmless objects such as water droplets are distinguished from such critical defects without additional classification. MCIP and HEUFT reflexx A.I. identify rust in the finish area. The integrity of Applied Colour Labels (ACL) can also be checked in detail. Even in the ACL area itself, cracks and defects are reliably detected. In addition, MCIP dark field illumination also reveals chips at the bottom edge, which often remain completely hidden in bright field.

Deep learning base inspection

With the latest HEUFT AI, even more is now possible when it comes to optical base and finish inspection, increasing the sensitivity of detection, making the previously invisible visible, competently distinguishing critical defects from cosmetic ones, and sustainably minimising the false rejection rate. In addition, it shortens commissioning times and delivers more stable results even under fluctuating ambient conditions. The empty bottle inspector can be installed in an optimally preconfigured state. Lengthy brand-specific teach-in procedures are largely eliminated. Whereas previously a separate algorithm was required for virtually every bottle variety and shape in order to centre its base so precisely that the inspection covered it completely gapless, now a single algorithm is sufficient. Based on their symmetry as the only centring parameter, this is suitable for a wide variety of bottle types – regardless of knurling marks, embossing and other brand-specific characteristics. The deep learning AI is already pre-trained for intelligent base inspection of empty standard glass and PET bottles: thousands of trained base images of bottles without any defects reveal the enormous variety of such good bottles. Although they are similar, they never are seen exactly the same due to variations in material, brightness or colour, among other things.

Reusable PET bottles are also often affected by wear and scuffing, or there are water droplets on their base. HEUFT reflexx A.I. clearly decides whether such structures are still within tolerance or represent a faulty deviation from the good images trained in the multi-layered neural model. It is no longer each individual detail, but the entire recognition image as a whole that is classified as ‘good’ or ‘bad’. Anomaly detection ensures that not only already specified errors are found, but also newly occurring ones. This even applies to transparent, non-polarising film in PET bottles. On the other hand, the proportion of containers that the inspector considers defective due to non-critical tolerances in the base area is drastically reduced – and with it the false rejection rate. This increases the efficiency and productivity of entire filling lines and protects against unnecessary packaging waste!

Deep learning finish inspection

For finish inspection, too, countless images of standard beer bottles with no defects have already been trained into the deep learning model, even though they differ slightly from one another in terms of shape, glass thickness or colouring, among other things. The result is a huge pool of good images within the tolerance range, so that the AI automatically evaluates all deviating structures and objects as errors. Nothing undefined is overlooked anymore; empty bottles with critical defects are reliably detected and consistently rejected. If the deviations are just cosmetic, they can stay in the line as desired and can be refilled without any worries. Together with an even more stable setup of the empty bottle inspector, this also increases the efficiency of entire bottling lines!

Thanks to HEUFT reflexx A.I. and MCIP (see above), there is now also a comprehensive inspection solution for a wide variety of diameters and shapes of wide-neck finishes, which always covers their sealing surface gapless. Focused lighting is used to generate images that contain significantly fewer interfering structures and show a reflection ring on the sealing surface of the neck that is twice as large as before. Where it is interrupted or blurred, there are cracks or chips, which can now be detected even more reliably with the new high-performance optics.

The AI for base centring and pre-trained base and finish inspection is already integrated into the X-ray-assisted HEUFT InLine II IX empty bottle inspector and can be experienced at drinktec in Munich both in the exhibited device itself and at particular enlightenment stations. The latter also applies to intelligent wide-neck finish and sidewall inspection with MCIP and HEUFT reflexx A.I.. Take a deeper look: Stand B4 121/321.