Irradiating organic products?

Those who fill and package organic food often shy away from using an X-ray inspection system in order to detect foreign objects. However a glass in glass detection with careful and precise pulsed X-rays is not only advisable but in many cases also compliant with the strict regulations in this growing sector particularly when it comes to environmentally friendly glass packaging.

It can be heard over and over again that food from controlled organic cultivation and marked accordingly is generally not allowed to be irradiated. But this is only partially correct. In fact it is not permitted in this sector either to use ionising radiation in order to extend the shelf life of the product and possibly kill any microorganisms it may contain. However it is quite different regarding in-line inspection applications:

this is because the radiation intensity used for an X-ray based foreign object detection is much lower. Only very little radiation is needed if it is not being used to treat the food but merely check the production process. Therefore the use of ionising radiation in the case of organic products is perfectly permissible and common for measuring and testing purposes. Up to 0.5 gray is permitted by law for product testing but in practice only 0.0001 to 0.01 gray is usual. By contrast HEUFT systems with patented pulsed X-rays only emit 0.000015 gray per beam! That is more than 30,000 times lower than the 0.5 gray limit.

X-ray detection where there is an increased liability risk

Even Demeter e.V. the growers' association for biodynamic food, which applies the strictest criteria in Germany by far, largely prohibits the use of X-rays "for the purpose of detecting foreign objects". But not completely: businesses which are subject to "an increased liability risk" e.g. due to the danger of glass splinters contaminating the packaging and the product, which should not be underestimated, can apply for an exemption.

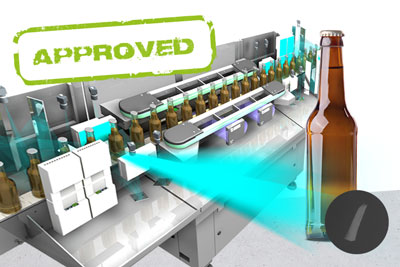

And the prospects are not bad at all that it will be granted for systems with the pulsed radiometric technology available exclusively from HEUFT for a careful and precise glass in glass detection due to their extremely low emission: in-house developed HEUFT X-ray strobes for a foreign object detection only generate a millisecond X-ray pulse at the moment when a product to be examined is actually in the detection area. Therefore they are mostly inactive in contrast to permanently activated X-ray scanners so that no radiation is emitted at all during up to 99 per cent of their operating time.

Careful glass in glass detection

Accordingly the X-ray assisted HEUFT InLine II IX can generally be used without hesitation in order to identify, among other things, minute glass splinters and defects in jars and bottles reliably even before they are filled with organic food. Because at this time the sensitive product is not in this primary packaging yet. And even if this is the case an end of line X-ray inspection with the modular systems of the HEUFT eXaminer II series is careful enough: the maximum dose emitted per measurement is less than 0.1 millisievert merely a hundredth of that which conventional X-ray devices emit on average. This corresponds to the natural radiation to which the organic product is exposed when it is only on the shelf at the HEUFT location in Burgbrohl for three days. And no radiation whatsoever can be detected in the product and packaging after the inspection.