Full case inspection

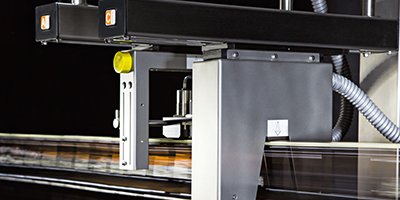

HEUFT logic II LF

Checking outer packaging specifically: precise full case inspection.

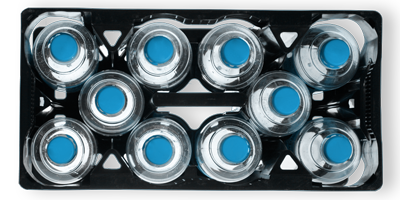

The HEUFT logic II LF checks the quality features of newly packed bottle crates, trays and cardboard boxes. It detects external features such as deformations, raised cardboard box flaps, incorrect colours and logos just as reliably as containers inside the outer packaging which are missing, clearly underfilled, lying, too high or incorrectly closed.

Checking the contents

What counts is what's inside: presence and completeness checks.

Everything in the crate: The HEUFT logic II LF can be equipped with various technologies to check the contents of freshly packed full containers.

Read more...

Ultrasonic detection checks whether the containers are present in the crate. Infrared detection uses the reflection behavior of the closures to check that all containers are present. If these are made of metal or foil, inductive proximity switches deliver precise results. In addition to the HEUFT reflexx A.I. camera in a top-down arrangement, X-ray inspection offers maximum detection reliability. It is the first choice, especially during the inspection of completely sealed, non-transparent outer packaging such as cartons. If containers are missing, the absorption coefficient of the X-ray beam emitted in measured doses changes. This means that even containers that are lying down or are severely underfilled and possibly leaking are identified.

Fullscreen

Height check

Show profile: at the height of its powers.

Warped compartments, foreign objects under the bottle, broken or deformed containers: various factors lead to deviating height ratios in the container. The HEUFT logic II LF registers them even before the actual container inspection with an infrared photocell just above the top edge of the container and a reflector on the opposite side of the conveyor belt. If the infrared light beam is interrupted, it can be assumed that the package is too high: the contents protrude above the top edge. To prevent damage during subsequent detection, a corresponding message is displayed and the conveyor belt is stopped.

Fullscreen

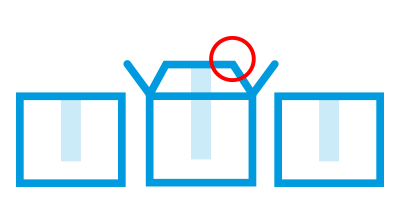

Carton flap check

Detecting protruding lids: Verifying that the carton is closed.

Misaligned, protruding, not correctly sealed: If this is the case with the lids of beverage cartons, it not only looks unattractive. It also jeopardizes the effectiveness of the outer packaging and the safety of the products it contains.

Read more...

The HEUFT logic II LF therefore checks the position and correct fit of the flaps and thus the sealing of the entire package. Sensors scan the edges to do this. If they are covered by protruding lids, the measured values change. This ensures that affected outer packaging is reliably detected. IR cameras can also be used in the tray packer as an option to ensure that the hot melt adhesive has been applied correctly immediately after the cartons have been sealed.

Fullscreen

Rejecting faulty products and sampling.

Prevent recalls: reliable rejection of faulty containers.

Out with it! Safety and precision in error detection are only useful if the affected products are actually removed from circulation. To ensure that incompletely filled and faulty crates, cartons, and trays are removed from the production flow, the HEUFT logic II LF either issues a belt stop signal or controls the appropriate rejection system, such as the HEUFT maxi-laner. This also enables random sampling for internal quality assurance.

Fullscreen

Product monitoring and self-tests

Playing it safe: exact product tracking and regular self-tests.

Always knowing the current location of a particular product: each one is tracked precisely for this. This ensures that none remain uninspected.

Read more...

The integrated reject verification checks that each product identified as faulty is really removed. Standard test programs guarantee a regular examination of the detection performance. Network-based continuous documenting and long-term archiving of the results.

Easy brand changes

Automatic changeover: Automatic adjustment of the detection units.

Simply easy: With the HEUFT logic II LF, changing to different container types, colors, or formats is child's play, even for inexperienced users. This is already ensured by the self-explanatory HEUFT NaVi user guidance of the compact device. An integrated changeover assistant provides effective step-by-step assistance during the adjustment of the recognition units. Incorrect settings are thus practically impossible, and excessive downtimes and the associated losses in productivity are no longer an issue.

Optional additional functions

Making even more possible: extensions to the range of functions.

Thanks to its modular design, the HEUFT logic II LF can be expanded at any time. An additional HEUFT reflexx A.I. camera ensures reliable differentiation between different container colors and logos for maximum brand purity.

To ensure that differently colored promotional stickers and symbols do not distort the result, three measuring windows and evaluation methods can be defined individually. For clear product identification, up to 13-digit EAN and UPC barcodes on the outer wall of the respective full container are also checked using intelligent optics.

Fullscreen

HEUFT SPECTRUM II

Simple automation: Universal device platform for maximum performance.

Highly automated, universal, powerful: HEUFT SPECTRUM II ensures optimum detection and operational reliability during in-line inspection for sustainable product quality and line efficiency. The comprehensive multi-processing control unit for different modules, systems, and applications impresses with its exceptional degree of automation. This also applies to its function as a basic device for the HEUFT logic II LF. Type and format changes can be carried out in just a few simple steps. The unique human-machine interface of the universal device platform is self-explanatory. This effectively reduces the strain on human resources. Hardware and software of the latest generation developed in-house and a future-proof network connection deliver maximum computing power and real-time data transmission. The result: maximum precision during reliable product tracking, inspection, and rejection.

Fullscreen

HEUFT reflexx A.I.

Simply detecting more: real-time image processing with artificial intelligence.

The AI discipline of machine learning for targeted object classification has been mastered by our self-developed image processing since 2010! And since then it has learned a lot: intelligent filters distinguish drops of water on the container from air bubbles in the glass and even make it possible to identify tiny defects which are hidden behind ACLs or embossings. HEUFT reflexx A.I. now also uses deep learning!

Read more...

Appropriately trained neural networks are used for example to denoise X-ray images or to find dangerous foreign objects in structured products and to reliably distinguish them from good objects which are extremely similar in their shape, size and density. With true artificial intelligence, the hardware and software from our own development and production again increases detection reliability - and minimises the false rejection rate. The smart image processing can be directly integrated into the HEUFT reflexx A.I. camera which was developed in-house and which processes and evaluates its own images directly in real time and raises the adaptive image analysis to a top level.

Fullscreen

HEUFT NaVi

Simply know what to do: self-explanatory user guidance.

Intuitive, individual, easy: no prior knowledge is required to operate HEUFT SPECTRUM IIsystems safely. The HEUFT NaVi user guidance is self-explanatory and supports the respective user step by step.An RFID login with user-specific access rights provides clarity and makes the work of the respective user simply easy: on the tidy touchscreen user interface with a flat menu structure, integrated tutorials and tailor-made help tools, they only see what they actually need to optimally perform their specific tasks. Targeted and focused on the essentials, the HEUFT NaVi user guidance makes the safe operation of HEUFT systems simply easy!

Fullscreen

HEUFT checkPoints

Simply see where something needs to be done: problem-free localization.

Clear, direct, and to the point: in the rare cases where manual intervention is necessary, the user can find their way around immediately. In addition to the information provided by HEUFT NaVi, eye-catching HEUFT checkPoints make it clear at a glance exactly where action is required. In the event of a fault, the orange tags flash not only on the touchscreen, but also on the component concerned. It can be located immediately without a long search. This saves time, conserves human resources, reduces downtime and thus increases productivity.

Network technologies

Networking everything: online connection for increased efficiency and quality.

Information transmission in real time, production data acquisition, line analysis and remote maintenance: networking is the answer!

Read more...

HEUFT systems have future-proof network interfaces (Gigabit Ethernet and TCP / IP) for an online connection via the Internet and the database interface (SQL / DDE) for top line efficiency and an optimum quality management with considerably faster and easier workflows. Therefore production data, shift records, productivity faults and HACCP limit value analyses are available network-wide. The result: early identification of quality and efficiency problems. The firewall protected direct connection to the HEUFT TeleService makes competent remote maintenance possible all around the clock.

HEUFT case rejector

Removing faulty crates from circulation: The right rejector for all cases.

Discharging, rejecting and distributing: HEUFT rejection systems for packaging remove faulty crates, cardboard boxes, trays or shrink wrap packages reliably from the production flow. They achieve maximum performance optimally matched to their respective task with regard to precision and carefulness.

- gapless quality assurance of filled secondary packaging

- up to 32 varieties and production programs

- precise inspection of up to 7,200 full containers per hour

- 1 m/sec maximum belt speed

- intelligent combination of sensor technology, HEUFT reflexx A.I. cameras, and X-ray technology

- up to three HEUFT reflexx A.I. cameras

- up to two X-ray detection systems

- up to two rejection systems

- rejecting faulty products and random sampling

- container tracking independent of speed

- easy integration into existing systems

- fully automatic product changeovers

- simple retrofitting and upgrading thanks to modular design

- compact, easy-to-clean design

- online connection for production data acquisition and remote maintenance with the HEUFT TeleService