World class production quality

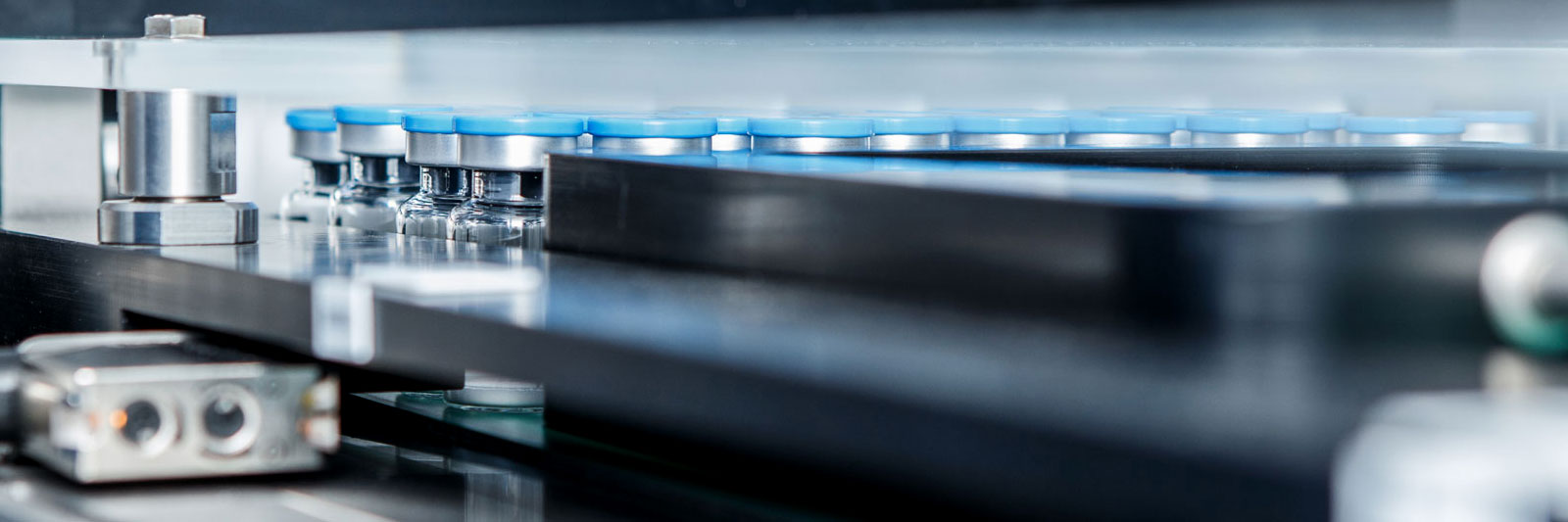

Installation and commissioning have been completed, a GMP compliant in-line quality assurance has been ensured and production can begin shortly: the HEUFT spotter II PHS will commence operation in the new Relatox plant of the Russian pharmaceutical giant NPO Microgen in Ufa. A real milestone which both companies acknowledged at ACHEMA in Frankfurt.

Sergey Niklaevich Goryunov, First Deputy General Director at NPO Microgen, came to the HEUFT stand on the very first day of the exhibition where the new, but already tried and tested, full vial inspector was just celebrating its ACHEMA premiere. For Mr Goryunov it is an elementary component of the new plant for the production and packaging of "Relatox, the first and only Russian botulinum toxin type A preparation". After all the system helps to protect the packaging and product safety of the Botulotoxin substitute for neurological and cosmetic applications sustainably. "And as one of the largest producers of immunobiological products in Russia we pay particular attention to product safety and quality control," according to Mr Goryunov. "For this reason we have decided to invest in a fully automated inspection system which makes a complete quality and conformity check in the final phase of the Relatox production possible."

However finding a suitable device was not so easy: "We had several meetings, discussions and negotiations with the world's leading suppliers of corresponding procedures and technologies before the project started. However only one company was able to offer a concept which not only ensured an effective solution for simultaneously safeguarding different ways to check finished preparations in vials but also compact dimensions to integrate the multifunctional system into a limited production space." Namely the unrivalled extensively equipped HEUFT spotter II PHS is extremely space-saving and efficient as a linear machine with neither carousel nor container specific change parts.

Multifunctional and space-saving

The successful integration and commissioning of the compact system is the result of genuine "teamwork at all levels from planning to the completion of the machine" according to the First Deputy General Director at NPO Microgen. Therefore HEUFT has succeeded in "taking into account all the specific features of our production and all the subtleties of the industry". The HEUFT spotter II PHS examines each individual full vial completely without gaps in the smallest possible space at NPO Microgen in Ufa:

it carries out a complete inspection of all the closure elements from the flanged edge, stopper position to the integrity of the flip off cap. This ensures the tightness of the full vial and thus the microbial purity of the lyophilisate contained in it. The integrated fill level detection makes sure that the dosage is correct. In addition foreign matter such as hair or fibre is reliably identified in the primary packaging material. "And the detection of scratches and cracks in the glass gives us an additional guarantee for the high quality of our products," according to Mr Goryunov.

Qualified and validated

The pulsed X-ray technology available exclusively from HEUFT can be retrofitted at any time. For example solid foreign objects such as glass splinters or metal particles can also be identified carefully and precisely in the lyo product if the amount of product in the vial should increase.

Either way the First Deputy General Director at NPO Microgen is extremely satisfied with the detection, rejection and operational reliability of the innovative inspection system for the pharmaceutical industry. "The requirements for world class production will be fully met by it." It will comply with Good Manufacturing Practice (GMP) standards as does the complete line – and thus with the international quality assurance requirements for the manufacture of pharmaceuticals. "The new production area with a whole range of technological equipment has successfully passed qualification and validation – including the inspection system," Mr Goryunov is pleased to say. "That alone speaks for itself."

Therefore the successful commissioning of the HEUFT spotter II PHS is an important milestone for him on the "strategically important path of modernisation" which NPO Microgen is continuing to forge ahead with not only with the new Relatox plant in Ufa.