More performance when inspecting empty cans

The further developed HEUFT canLine II now achieves even greater precision and performance when inspecting cans at high speed before they are filled thanks to new HDR technology and optical character recognition with deep learning capability.

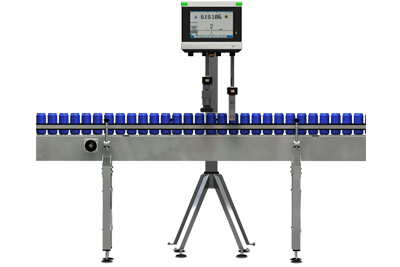

The compact HEUFT canLine II is one of the most powerful solutions on the market when it comes to checking the quality of empty beverage cans. Its intelligent top-down inspection has already achieved such a depth of field that oval deformations and indentations on the flange edge, as well as dents and contamination on the inner sidewall and foreign objects on the can base, can all be detected with a single camera. Now, its resolution has been quadrupled. And the newly integrated HDR technology also optimises the illumination of all these areas, so that the complete inspection has become even more reliable at a performance level of up to 144,000 empty cans per hour.

High Dynamic Range Images (HDRI) compensate for any light reflections and shadows on the can flange or inner walls. This not only ensures the necessary image sharpness everywhere but also truly homogeneous illumination for full coverage and a clear view for the inspection of the empty cans – even at the highest speeds. This ensures that containers which cannot be reliably filled and closed are detected in time by the HEUFT reflexx A.I. camera and rejected before the safety and quality of the end product is put at risk as well as the efficiency and productivity of complete canning lines.

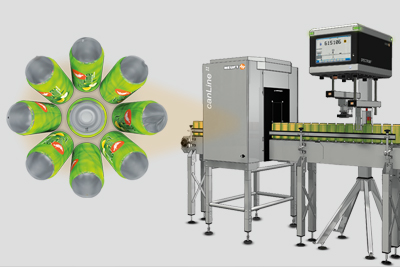

More intelligence in OCV

A new type of technology for intelligent Original Character Verification (OCV), which can now be connected to HEUFT canLine II empty can inspectors, also helps to maintain output and avoid unwanted line stoppages. It was recently presented to the public for the first time at BrauBeviale 2024. The best-before date (BBD), for example, which is applied to the outside of the base of each individual empty can using an inkjet, is reliably detected and verified by another intelligent bottom-up camera developed and manufactured in-house. And thanks to self-programmed deep learning AI, this is even possible when the typeface is not optimal!

Each individual character applied by an inkjet consists of a collection of individual ink dots that combine to form numbers or letters. Depending on the configuration and operating status of the inkjet system, creeping display problems can occur: individual dots slip and no longer land exactly where they are supposed to. letters and lines of text distort, blur and smear. The entire typeface becomes less precise and increasingly difficult to read.

Text recognition with the naked eye is already difficult – and practically impossible during low container transport speeds. However, the HEUFT reflexx A.I camera, intelligent image processing and deep learning when analysing images make it possible to reliably detect codes of decreasing quality during the transport of containers at speeds of up to 72,000 empty cans per hour!

More detection reliability

This is the result of significantly improved separation. Instead of centring the entire text block at once, each character is now centred individually. As a result, if one of them slips out of place, this is no longer a problem. On the other hand, the deep learning algorithm independently recognises the different appearances of the individual letters and digits that have been previously taught in and evaluates them individually.

The deep learning-capable image processing increases the detection and rejection reliability during empty can inspection and OCV as well as the quadrupled resolution of the HEUFT reflexx A.I cameras used and the newly integrated HDR technology. The full integrity of the packaging is thus ensured as is the desired quality of the finished product.

More availability, efficiency and productivity

Both processes also help to prevent unwanted production stops: blockages of the filler-capper block due to deformed, non-closable cans are avoided. The false rejection rate, i.e. the proportion of faultless empty containers erroneously removed from production, continues to fall.

And even in challenging cases, difficult-to-read inkjet codes such as distorted best-before dates are detected and verified so reliably that unscheduled line stops, for example for inkjet maintenance and recalibration, are no longer an issue. Even if print quality is suboptimal, production does not have to be interrupted immediately. The availability and efficiency of the entire canning line remain at the highest level. And so does its output.